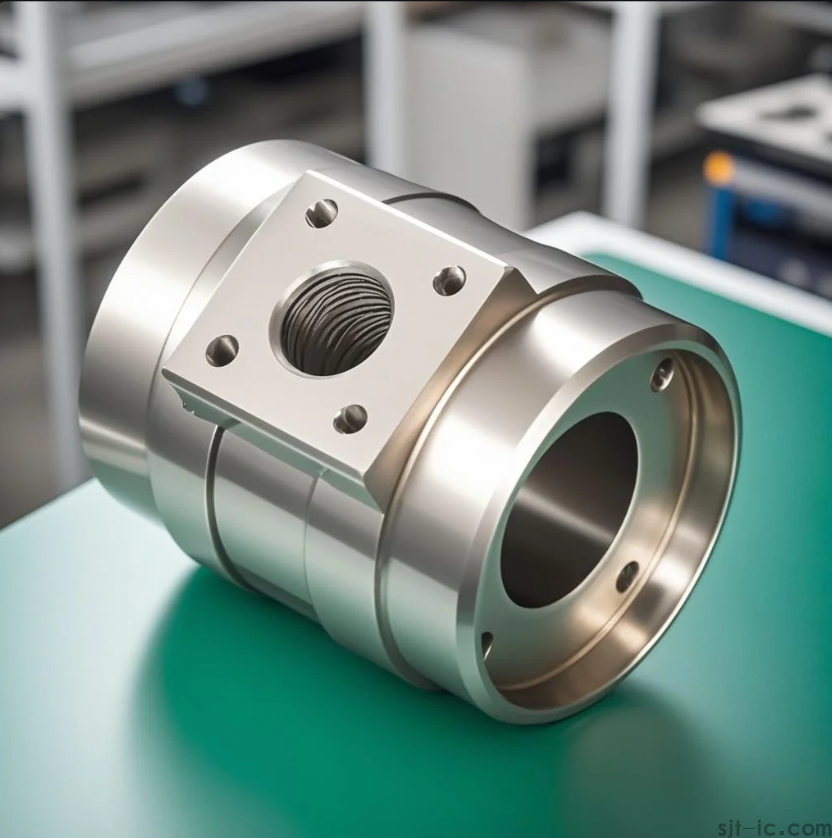

As a professional CNC Machining service provider, EMAR Company specializes in delivering high-precision components for industries ranging from aerospace to medical devices. One of the most common questions we receive from engineers and procurement managers is: How precise can CNC 3-axis machining actually get? This article will break down the technical capabilities and real-world applications of this fundamental machining process.

Understanding CNC 3-Axis Machining Precision

Standard 3-axis CNC milling typically achieves tolerances between ±.005" (±.127mm) to ±.0005" (±.0127mm) depending on material, machine calibration, and operator expertise. At EMAR, our ISO 9001-certified workshops maintain machines capable of holding ±.001" (±.025mm) as standard production tolerance for most metals and plastics.

Key Factors Affecting Accuracy

1. Machine Rigidity: Our German-engineered CNC mills minimize vibration for micron-level repeatability

2. Tooling Quality: We use Swiss-made carbide end mills with diameter tolerances of ±.0002"

3. Temperature Control: Climate-controlled workshops prevent thermal expansion errors

4. Metrology Equipment:

CMM inspection verifies parts to .0001" (2.5μm) accuracy

When to Choose 3-Axis vs. Multi-Axis

While 5-axis machining offers greater flexibility, 3-axis remains the cost-effective solution for:

- Flat or prismatic parts

- High-volume production runs

- Materials like aluminum, brass, and engineering plastics

Our engineers can advise whether your project requires advanced multi-axis capabilities or can achieve target tolerances through optimized 3-axis programming.

With over 15 years of machining experience, EMAR provides free DFM analysis to help clients balance precision requirements with production efficiency. Visit our website to upload your CAD files for instant quoting.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque