Understanding the Critical Aspects of CNC Mold Machining

CNC mold machining is a specialized process that requires meticulous attention to detail to ensure precision and quality. As a leading CNC Machining service provider, EMAR Company emphasizes several key factors that must be considered during the mold manufacturing process.

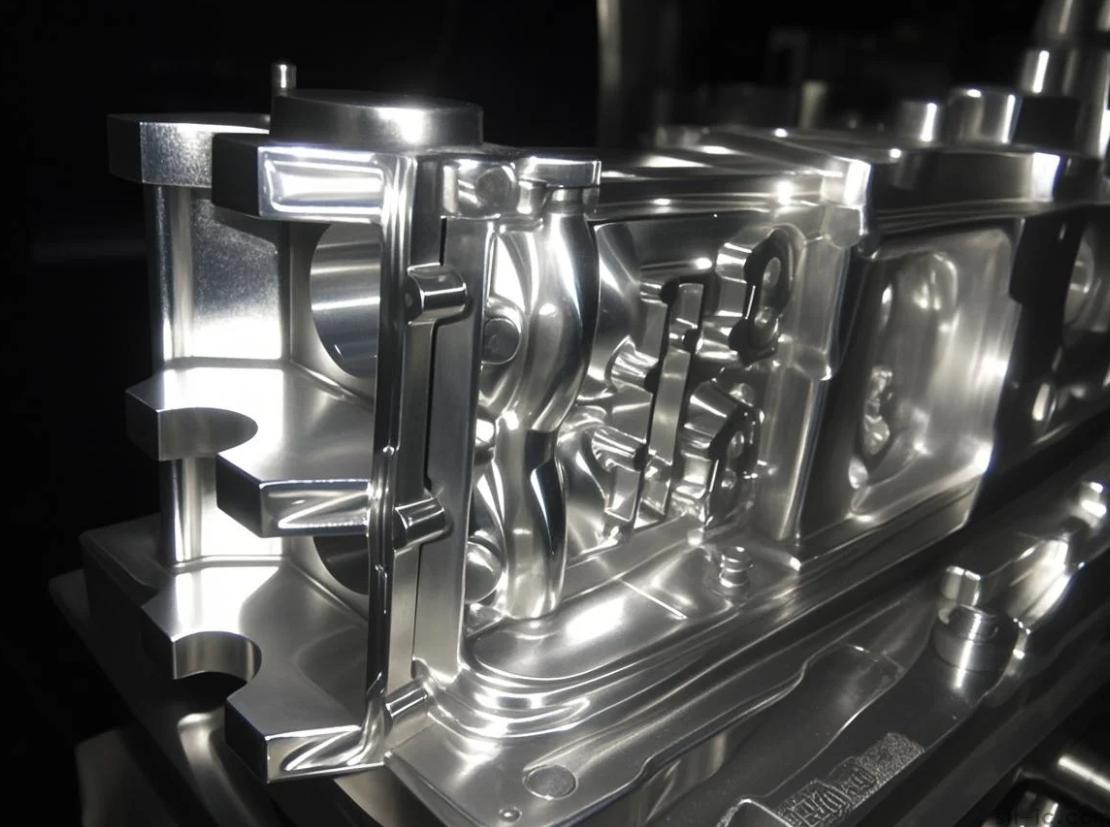

Material Selection and Preparation

The foundation of successful CNC mold machining begins with proper material selection. Factors such as hardness, thermal stability, and machinability must be carefully evaluated. Common materials include tool steels, aluminum alloys, and copper alloys, each requiring specific machining approaches.

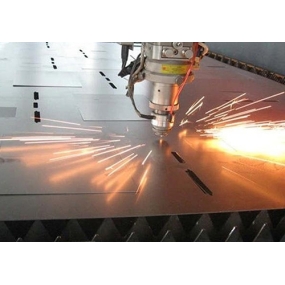

Precision Tooling and Machine Calibration

High-precision tooling is essential for mold manufacturing. The cutting tools must be properly selected based on the material and geometry of the mold. Regular machine calibration and maintenance are crucial to maintain the required tolerances, typically within ±.01mm for precision molds.

Coolant and Lubrication Management

Proper coolant application is vital in CNC mold machining to prevent thermal deformation of both the workpiece and cutting tools. The choice of coolant and its application method can significantly impact surface finish and tool life.

Surface Finish Considerations

Mold surfaces often require exceptional finishes to ensure proper part release and longevity. Post-machining processes such as polishing, texturing, or coating may be necessary depending on the application requirements.

Quality Control and Inspection

Rigorous inspection procedures using coordinate measuring machines (CMM) and optical comparators ensure that the finished mold meets all specifications. EMAR Company implements a comprehensive quality management system to guarantee the highest standards in every project.

Why Choose EMAR Company for Your CNC Mold Machining Needs

With years of experience in precision CNC machining, EMAR Company offers state-of-the-art equipment, skilled technicians, and a commitment to quality that sets us apart. Our expertise in mold manufacturing ensures that your projects are completed with the highest level of precision and efficiency.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque