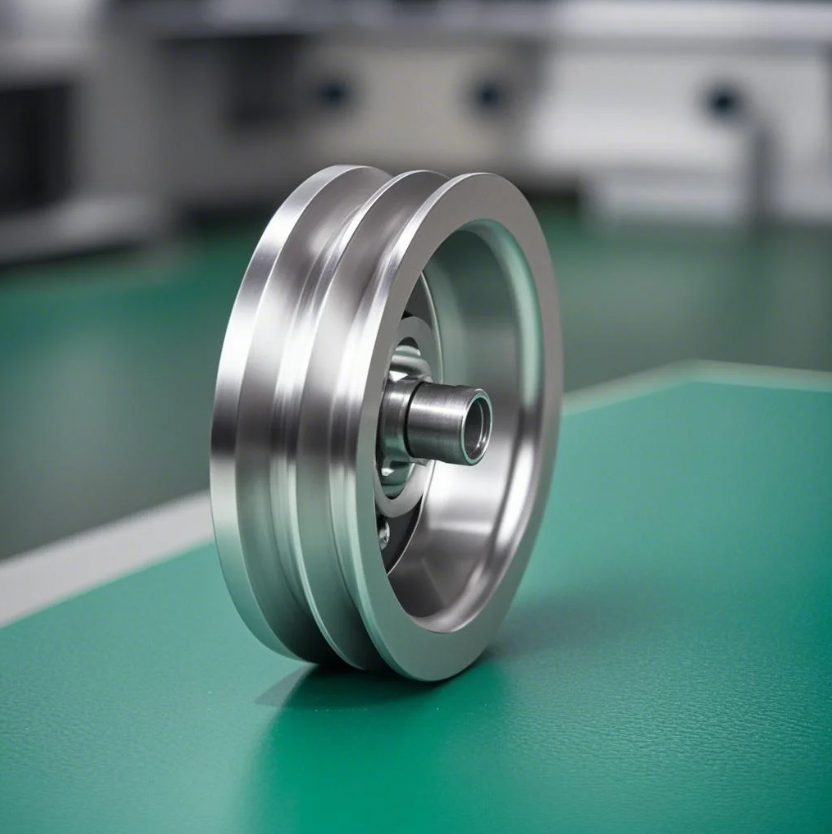

Understanding CNC Die Casting Product Processing

CNC die casting product processing is a precision manufacturing technique that combines die casting and CNC Machining to produce high-quality metal components with tight tolerances. This process is widely used in industries such as automotive, aerospace, and electronics due to its efficiency and ability to create complex geometries.

Key Steps in CNC Die Casting Product Processing

The CNC die casting product processing workflow involves several critical stages:

- Die Casting: Molten metal is injected into a steel mold under high pressure to form a near-net-shape part.

- CNC Machining: The cast part undergoes precision machining to achieve final dimensions and surface finishes.

- Quality Inspection: Advanced measuring equipment verifies dimensional accuracy and surface quality.

Advantages of Choosing EMAR for Your CNC Die Casting Needs

At EMAR, we specialize in CNC die casting product processing with:

- State-of-the-art CNC machining centers capable of ±.01mm precision

- Extensive experience with aluminum, zinc, and magnesium alloys

- Comprehensive quality control systems meeting ISO 9001 standards

- Efficient production processes that reduce lead times by 30% compared to industry averages

Applications of CNC Processed Die Cast Products

Our CNC die casting solutions serve diverse applications including:

- Automotive components (engine parts, transmission housings)

- Electronic enclosures and heat sinks

- Industrial machinery parts

- Medical device components

Why Partner with EMAR for CNC Die Casting?

EMAR stands out in the CNC machining industry through our:

- Technical expertise in both die casting and precision machining

- Flexible production capabilities from prototyping to mass production

- Competitive pricing without compromising quality

- Dedicated engineering support throughout your project lifecycle

For superior CNC die casting product processing solutions, visit our website at https://www.sjt-ic.com/ or contact our technical team for a customized quotation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque