As a leading CNC precision metal parts machining service provider, EMAR Technology understands that accurate pricing is crucial for procurement managers and engineers when selecting manufacturing partners. This guide explains the key factors affecting CNC Machining quotations and how our company delivers optimal cost-performance solutions.

Factors Influencing CNC Machining Costs

1. Material Selection: Different metals (aluminum, stainless steel, brass, etc.) have varying raw material costs and machinability ratings that directly impact pricing.

2. Part Complexity: Complex geometries requiring multi-axis machining or special tooling increase production time and costs.

3. Surface Finish Requirements: Additional processes like anodizing or powder coating add to the total CNC machining quotation.

EMAR's Competitive Quotation Advantages

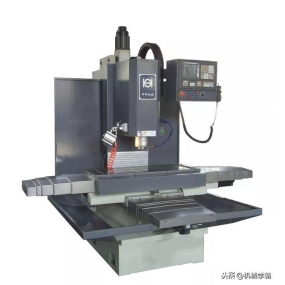

Our ISO 9001-certified facility in China combines advanced German DMG Mori machines with lean manufacturing principles to offer:

- Transparent cost breakdowns with no hidden fees

- Volume discounts for batch production

- DFM (Design for Manufacturing) suggestions to optimize costs

How to Get Your Custom Quote

Simply upload your CAD files to our website or contact our engineering team. We provide quotations within 24 hours for standard projects, including complete tolerance analysis and material recommendations.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque