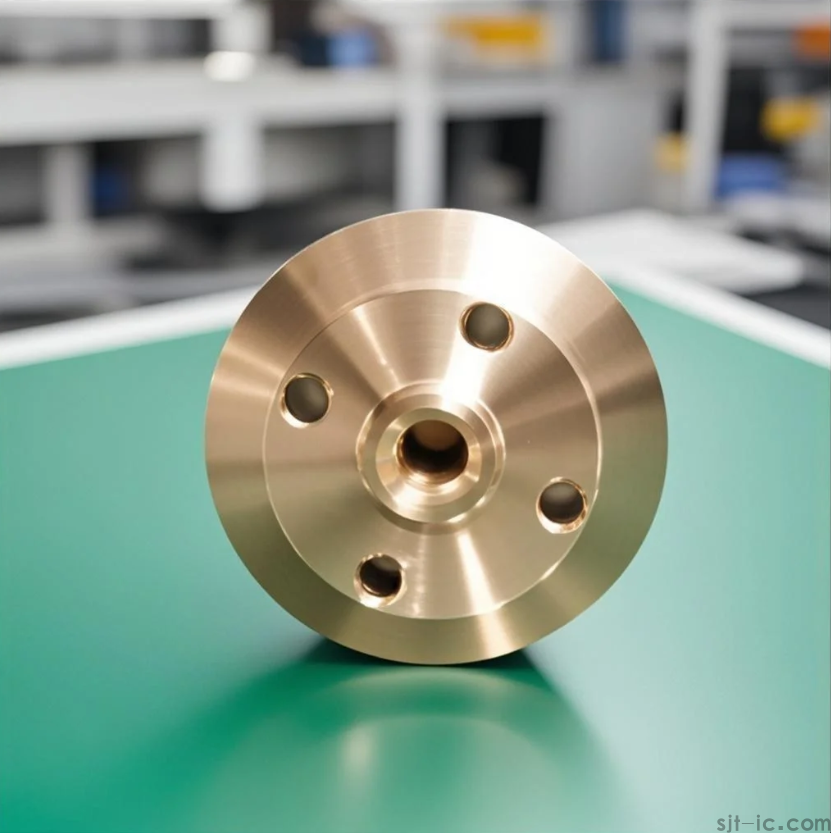

As a leading CNC precision copper parts manufacturer, EMAR Technology specializes in delivering high-quality custom machining solutions for industries requiring exceptional electrical conductivity and thermal performance.

Why Choose CNC Machining for Copper Components?

Copper's unique properties demand specialized CNC machining expertise. Our 5-axis CNC centers maintain ±.005mm tolerances while preventing material deformation, achieving surface finishes down to Ra .4μm for critical applications in electronics, automotive, and aerospace sectors.

Our Custom Machining Capabilities

EMAR's advanced machining center handles complex geometries for:

- High-precision copper connectors and terminals

- Custom heat sinks with optimized fin structures

- RF waveguide components with micron-level accuracy

- EDM electrodes for mold manufacturing

Quality Assurance Process

Every custom copper part undergoes rigorous inspection including CMM measurement, conductivity testing, and surface analysis. Our ISO 9001-certified process ensures consistent quality from prototype to mass production.

Technical Advantages

• Material Expertise: C11000, C10100, C17200, and other copper alloys

• Advanced Tooling: Diamond-coated cutters for extended tool life

• Secondary Processing: Plating, polishing, and anti-oxidation treatments

• Fast Turnaround: 3-5 day standard lead time for prototypes

Contact EMAR at www.sjt-ic.com to discuss your copper machining project requirements with our engineering team.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque