In modern manufacturing, CNC parts machining customization has become a critical solution for businesses requiring precision components. As a leading CNC Machining service provider, EMAR Company specializes in delivering tailored machining solutions that meet exact specifications while maintaining the highest quality standards.

What Is CNC Parts Machining Customization?

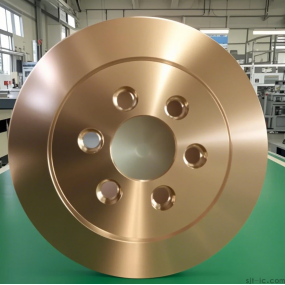

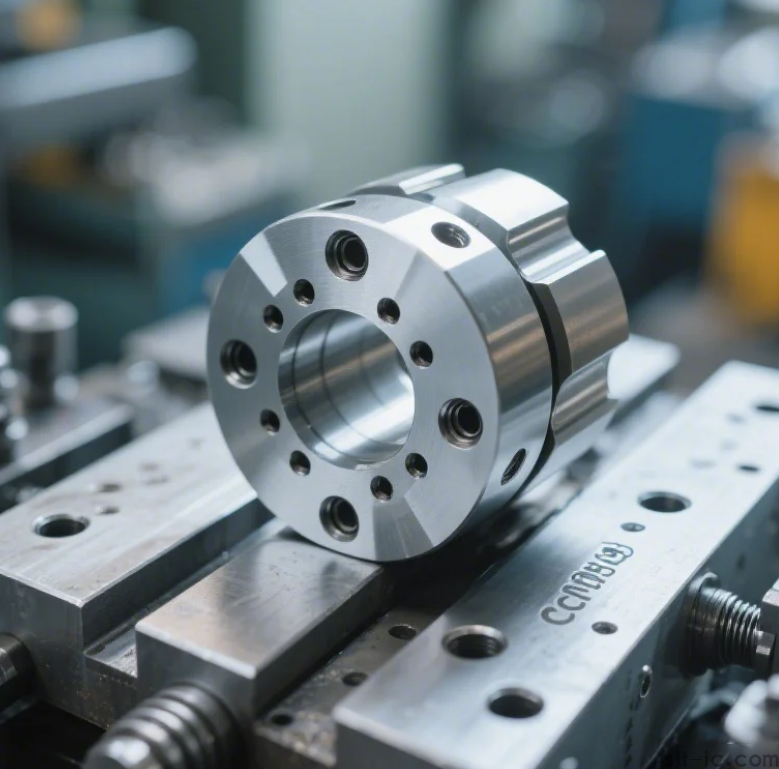

CNC parts machining customization refers to the process of manufacturing precision components using computer numerical control (CNC) technology according to client-specific designs and requirements. This service covers everything from prototype development to mass production, ensuring dimensional accuracy and material integrity for various industries including aerospace, automotive, and medical equipment.

Key Advantages of Our Custom CNC Machining Services

EMAR Company stands out in the CNC machining industry through:

Precision Engineering: ±.005mm tolerance capability for critical dimensions

Material Versatility: Expertise in machining aluminum, stainless steel, titanium, and engineering plastics

Advanced Equipment: State-of-the-art 5-axis CNC machines for complex geometries

Quality Assurance: ISO 9001-certified processes with full inspection reports

Fast Turnaround: Prototype delivery in as fast as 3 working days

Our CNC Machining Customization Process

The custom CNC parts manufacturing at EMAR follows a rigorous workflow:

Design Analysis: Our engineers review your CAD files for manufacturability

Material Selection: Recommending optimal materials based on application requirements

Programming: Creating optimized CNC toolpaths for efficiency and precision

Machining: Executing operations with real-time quality monitoring

Post-Processing: Applying surface treatments like anodizing or plating as needed

Final Inspection: Comprehensive quality check before shipment

Industries We Serve

Our CNC machining customization services support diverse sectors:

Automotive: Engine components, transmission parts, and custom fittings

Aerospace: Lightweight structural components and flight-critical parts

Medical: Surgical instruments and implantable device components

Electronics: Precision enclosures and heat dissipation solutions

Industrial Equipment: Custom gears, shafts, and hydraulic components

Why Choose EMAR for Your CNC Machining Needs?

With 15+ years of experience in precision manufacturing, EMAR Company combines technical expertise with customer-focused service. Our advantages include:

Competitive pricing without compromising quality

Strict confidentiality agreements for proprietary designs

One-stop solution from prototyping to full production

Dedicated project management for seamless communication

Contact our engineering team today to discuss your custom CNC machining project requirements and receive a free DFM analysis.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque