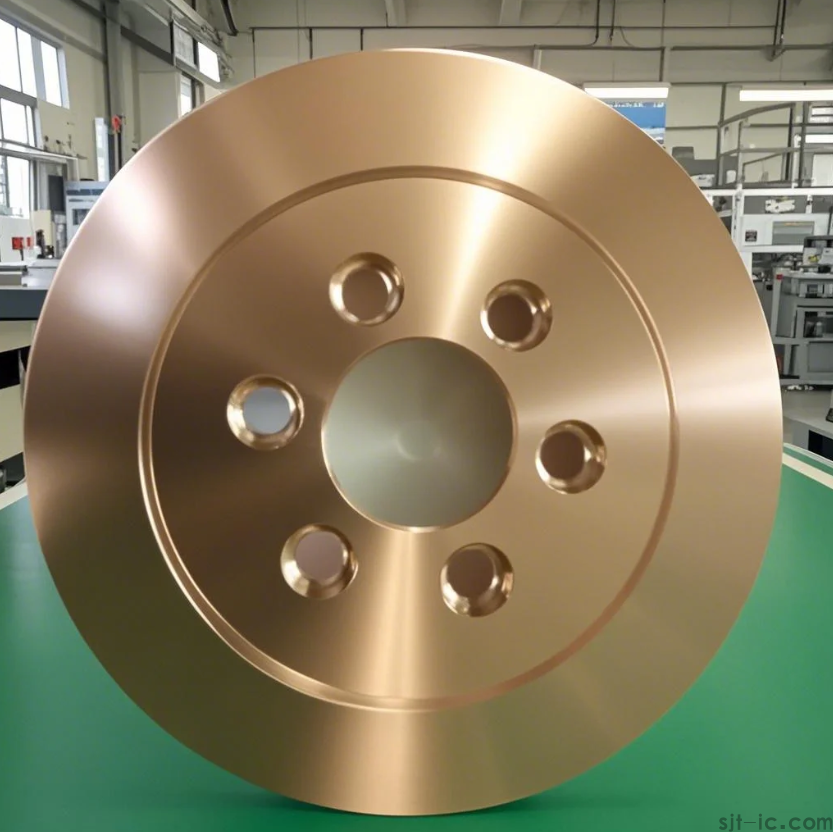

As a leading CNC copper parts manufacturing supplier, EMAR Technology specializes in precision machining of copper components for industries ranging from electronics to automotive. Our ISO-certified facility combines advanced CNC technology with decades of metallurgical expertise to deliver superior copper machined parts.

Why Choose Copper for CNC Machining?

Copper offers exceptional electrical conductivity, thermal resistance, and corrosion protection - making it ideal for electrical components, heat exchangers, and industrial machinery parts. Our CNC copper machining processes maintain these material properties while achieving tolerances within ±.005mm.

Our CNC Copper Machining Capabilities

EMAR's 5-axis CNC centers handle all copper alloys (C101-C110) with specialized tooling to prevent material galling. We offer:

- High-speed milling of complex copper geometries

- Micro-machining for miniature copper components

- Surface treatments including nickel plating and anti-oxidation coating

- 100% quality inspection with CMM measurement

Industry-Specific Copper Part Solutions

We manufacture precision copper parts for:

- Electrical: Busbars, connectors, terminals

- Automotive: Welding nozzles, bearing cages

- Medical: RF shielding components

- Industrial: Valve seats, heat sink assemblies

With rapid prototyping and batch production services, EMAR delivers copper machined parts with 15-20% faster lead times than industry averages. Contact our engineering team at www.sjt-ic.com for DFM analysis and instant quoting.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque