As a CNC Machining specialist at EMAR, we understand that tungsten steel CNC machining presents unique challenges requiring advanced technical solutions. This guide explores specialized processes to achieve precision results with this ultra-hard material.

Why Tungsten Steel Demands Specialized CNC Machining?

Tungsten steel (typically containing 85-95% tungsten) combines extreme hardness (HRA 80-90) with high density (15-18g/cm³), requiring:

Specialized tooling with PCD or cubic boron nitride tips

Optimized cutting parameters (typically 50-150 SFM)

Rigid machine tools with high torque capabilities

Advanced cooling strategies to prevent work hardening

Our 6-Step Tungsten Steel CNC Machining Process

EMAR's certified process ensures dimensional tolerances within ±.005mm for critical applications:

Material Analysis: XRF testing to verify alloy composition

Toolpath Optimization: Adaptive clearing strategies to reduce tool stress

Precision Roughing: Using .5-1.mm depth of cut with specialized end mills

Semi-Finishing: Achieving .1mm stock allowance

Final Machining: Diamond grinding for critical surfaces

Quality Verification: CMM inspection with 3D surface analysis

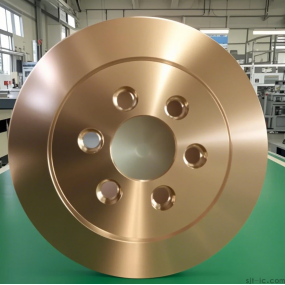

Key Applications of Machined Tungsten Components

Our CNC machining services produce tungsten parts for:

Radiation shielding in medical equipment

Precision counterweights in aerospace

Wear-resistant tooling inserts

High-temperature furnace components

Why Choose EMAR for Your Tungsten Machining Needs?

With 15+ years in exotic material machining, we offer:

ISO 9001:2015 certified processes

5-axis CNC capability for complex geometries

In-house metallurgical lab for material verification

Prototype to production volume flexibility

Contact our engineering team at EMAR to discuss your tungsten steel project requirements and receive a DFM analysis within 24 hours.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque