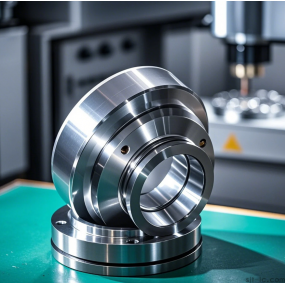

When sourcing CNC precision machining services, obtaining an accurate and competitive quotation is a top priority for procurement managers and engineers. As a trusted CNC Machining manufacturer, EMAR explains the key variables affecting pricing and how our solutions deliver unmatched cost-efficiency without compromising quality.

What Determines CNC Machining Costs?

Four primary factors influence CNC machining quotations:

Material Selection: Aerospace aluminum (6061/7075) costs 20-30% less than titanium alloys.

Part Complexity: A 5-axis milled component with ±.01mm tolerance may cost 2-3x more than simple turned parts.

Order Volume: Batch production of 1,000 units typically reduces per-part costs by 40-60% versus prototypes.

Secondary Processes: Anodizing adds $.50-$2.50 per part; precision grinding increases costs by 15-25%.

EMAR's Value-Driven Quoting Methodology

Our ISO 9001-certified facility employs proprietary cost-optimization strategies:

DFM Analysis: Our engineers review your CAD files within 4 business hours, suggesting design modifications that reduce machining time by 10-30%.

Smart Material Sourcing: Leveraging long-term contracts with metal suppliers to pass 8-12% material cost savings to clients.

Hybrid Manufacturing: Combining Swiss turning (for diameters under 32mm) and 5-axis milling to minimize setups and tool changes.

Transparent Pricing Structure

Unlike competitors with hidden fees, EMAR provides line-item breakdowns including:

Raw material costs (with Mill Test Certificates)

Machine time (calculated using CAM software simulations)

Quality control expenses (CMM inspection reports included free for orders >50 pieces)

Logistics options (DDP, FOB, or EXW terms available)

Case Example: A recent medical device client saved $18,500 annually after we recommended switching from 316L stainless steel to medical-grade PEEK for non-load-bearing components, reducing both material costs and machining time by 35%.

Get Your Custom Quote Today

Submit your technical drawings to EMAR's engineering team for a detailed quotation within 24 hours. All quotes include:

Volume pricing tiers (1-50pcs, 51-200pcs, 201-100pcs, 100+pcs)

Lead time commitments (standard: 5-7 days for prototypes, 10-15 days for production)

IP protection guarantee (NDA available upon request)

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque