Ever felt that sinking feeling when a massive, expensive piece of aluminum just... doesn't fit? 🤯 You're not alone. For engineers and procurement managers, the challenge of large aluminum structural components isn't just about size—it's about holding impossibly tight tolerances across that entire span. So, how do the pros tackle this? Let's break it down, step by step.

Why is Precision So Tricky with Big Aluminum Parts?

Think of it like this: aluminum is relatively soft. When you're machining a huge part, the tool pressure and the heat generated can actually make the material "move" during the process. This might suggest that the part itself is fighting against the machine. You set up for a perfect cut on one end, but by the time the tool reaches the other, things have shifted just enough to throw everything off. It's a battle against physics, not just the machine.

The Golden Rule: It Starts with the Right Aluminum Alloy

Not all aluminum is created equal for big jobs. While you might save a bit upfront on a softer grade, the cost of scrap parts later will hurt more.

Key Points:

- 🛠️ 6061-T6: This is the go-to for a reason. It's a great balance of strength, machinability, and weldability. It's predictable, which is half the battle for precision.

- 🛠️ 7075-T6 Need more strength? This one is fantastic, often called "aircraft-grade." But, it can be a bit trickier to machine without causing stress. You get the strength, but you trade a little ease.

The alloy you pick sets the stage for everything that follows. A poor choice here makes precision ten times harder.

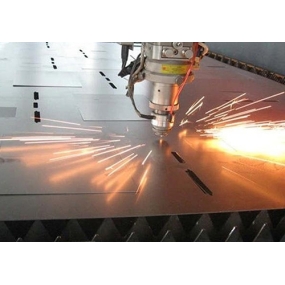

Your Machine Tool: The Bigger, The More Stable

You can't machine a boat on a desktop CNC router. For large structural parts, the machine's mass and rigidity are non-negotiable.

What to look for:

- 💪 Massive, rigid frame to dampen vibrations.

- 💪 Powerful torque at lower speeds to push through material without stalling.

- 💪 Advanced thermal control on the spindle and ball screws to prevent expansion from heat.

However, it's worth mentioning that even the best machine is only as good as the person programming it. A perfect machine with a bad program will still make a bad part.

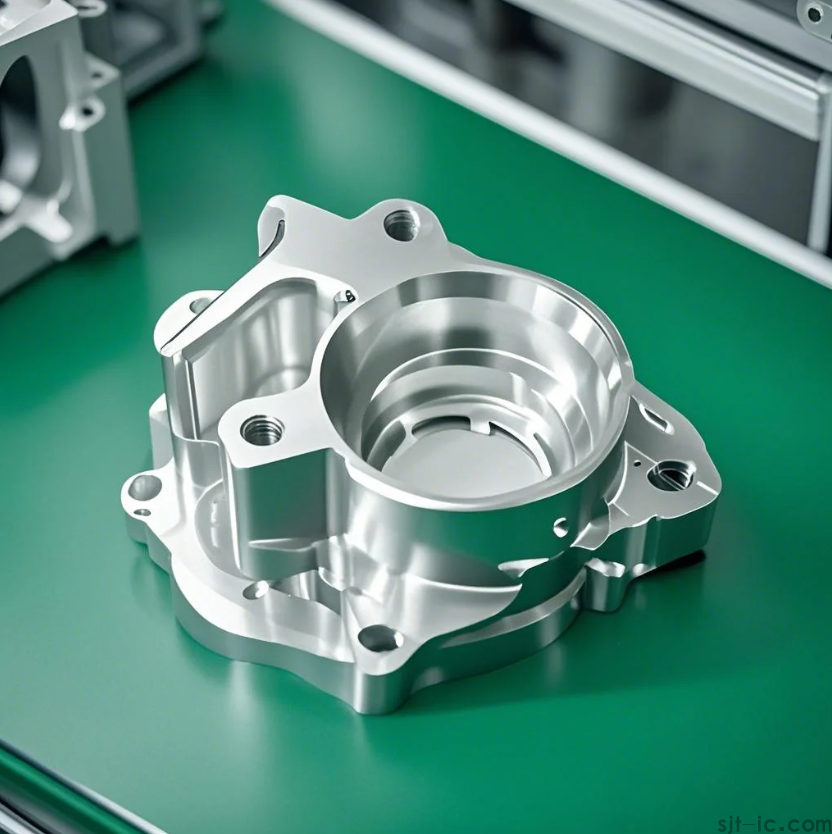

The Magic is in The Setup and Toolpath Strategy

This is where the real expertise comes in. Throwing a block of aluminum on the bed and hitting "go" is a recipe for disaster.

Pro Strategies We Use:

- 🧰 Custom Fixturing: We often design and build custom jigs and clamps that hold the part exactly where it needs to be, distributing clamping force to avoid distortion.

- 🧰 Multi-Step Machining: We rarely do it all in one go. A roughing pass removes the bulk of the material, letting stresses relax. Then, the part is re-setup for the final, light finishing passes that achieve the final dimensions and surface finish.

- 🧰 Smart Toolpaths: Using toolpaths that maintain a constant load on the cutter prevents shock to the material and reduces heat buildup, which is a major cause of inaccuracy.

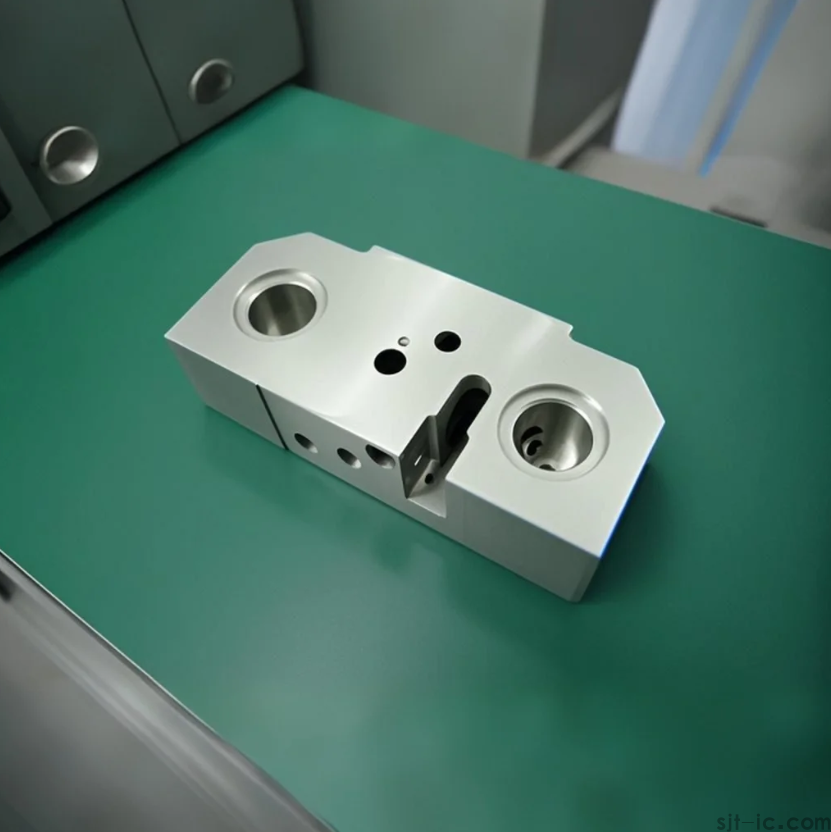

What About Quality Checks During The Process?

Waiting until the very end to check a part is like baking a cake without ever looking in the oven. For critical dimensions, we build in checks at intermediate stages.

This might involve using portable CMMs (Coordinate Measuring Machines) or laser scanners right on the shop floor. Catching a drift of a few "tenths" (a tenth is .0001 of an inch!) halfway through means we can adjust the program and save the part. This proactive approach is what separates a good shop from a great one.

So, precision in large aluminum machining isn't one single trick. It's a careful dance between material science, heavy-duty equipment, and, frankly, a lot of clever planning and foresight. It's about controlling every single variable you can, because the ones you can't control are trouble enough.

Struggling with a specific tolerance on a large aluminum component? Our engineers live for this stuff. 👉 Chat with our technical team now to see if we're a fit for your project.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque