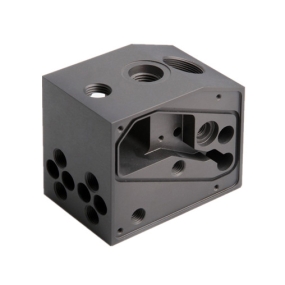

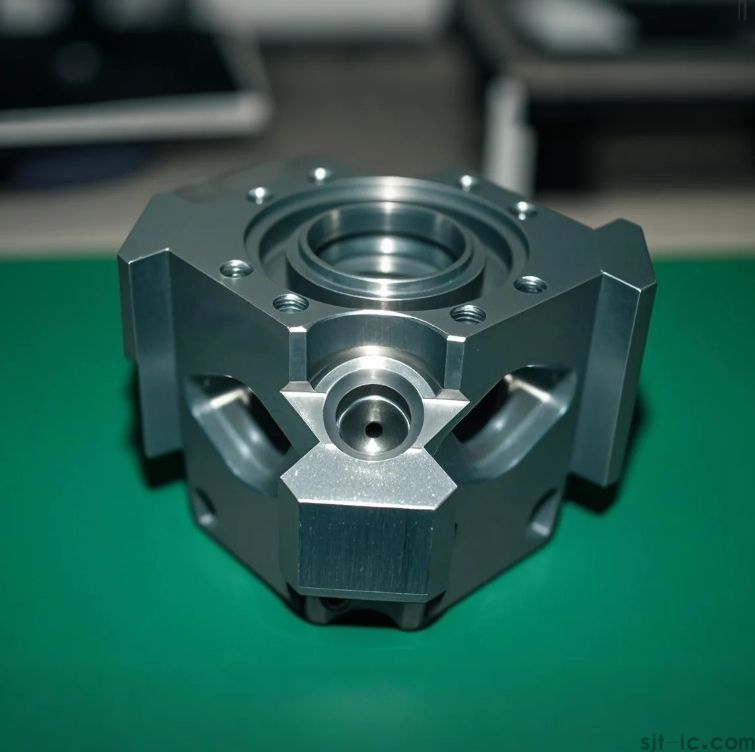

As a professional CNC aluminum parts manufacturer, EMAR Technology specializes in delivering high-precision custom machining solutions for industries ranging from aerospace to automotive. This article will explore the complete workflow of aluminum CNC Machining and how our expertise ensures superior results.

Why Choose CNC Machining for Aluminum Parts?

Aluminum is favored for its excellent machinability, strength-to-weight ratio, and corrosion resistance. Our CNC machining processes maintain tolerances within ±.01mm while achieving complex geometries that traditional methods cannot.

Our Custom Machining Process Flow

1. Design Analysis: Our engineers review your 3D models (STEP/IGES formats) to optimize manufacturability

2. Material Selection: We stock 6061, 7075, and other aerospace-grade aluminum alloys

3. Precision Machining: Using 5-axis CNC centers with high-speed spindles (up to 20,000 RPM)

4. Surface Treatment: Optional anodizing, powder coating, or chemical conversion coating

5. Quality Control: CMM inspection and ISO 9001-certified quality assurance

EMAR's Technical Advantages

• 15+ years of custom machining experience

• 50+ CNC machines with automatic tool changers

• Dedicated prototyping and mass production lines

• Strict compliance with AS910 and ITAR standards

Applications Across Industries

Our CNC aluminum components serve critical functions in:

Automotive: Lightweight engine brackets

Electronics: Heat sink enclosures

Medical: Sterilizable instrument housings

Robotics: Precision actuator parts

Contact EMAR at www.sjt-ic.com for your project requirements. Our engineering team provides DFM analysis within 24 hours and delivers prototypes in as fast as 3 working days.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque