Understanding CNC Non-Standard Metal Parts Machining

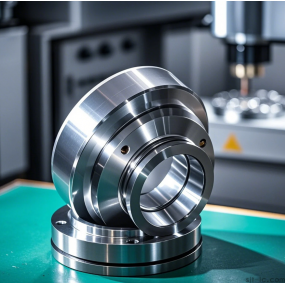

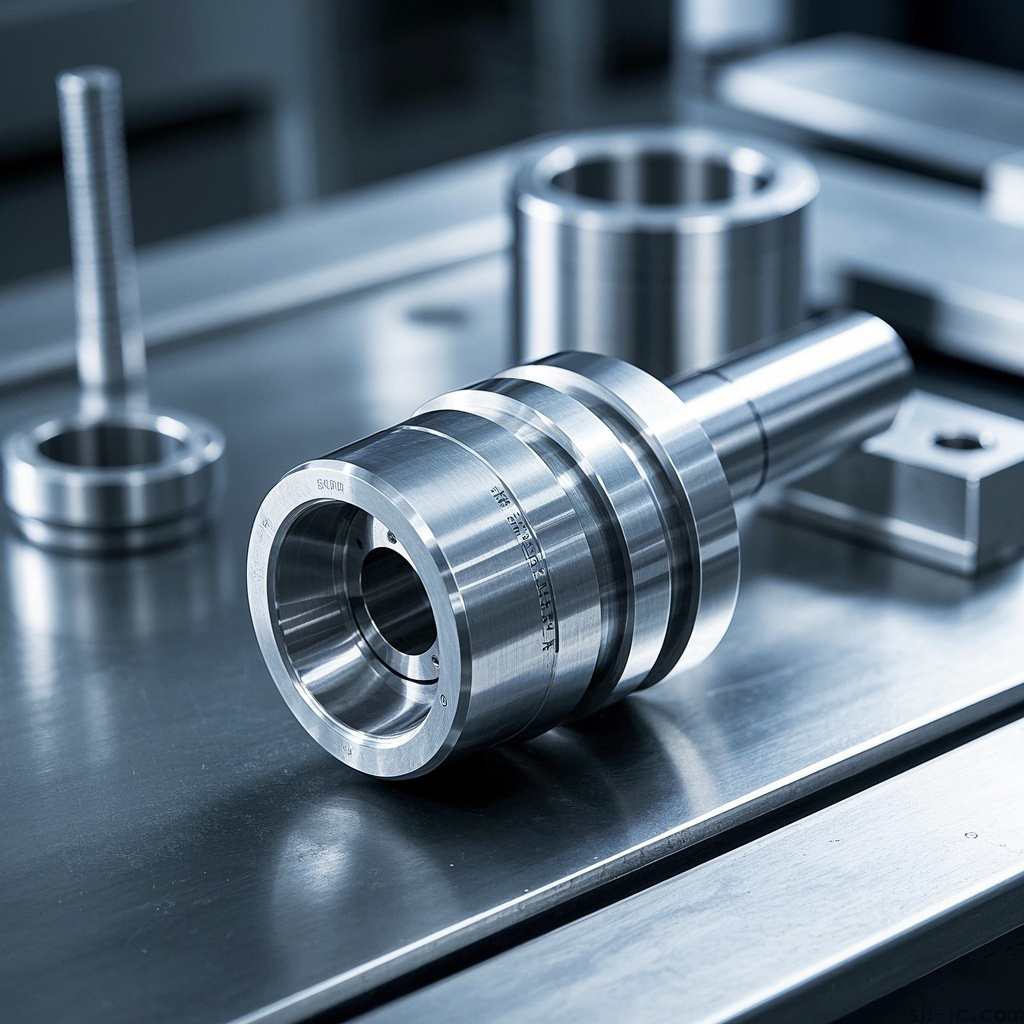

CNC non-standard metal parts machining refers to the process of creating custom, unique metal components that don't conform to standard specifications. At EMAR, we specialize in producing these precision components using advanced CNC technology to meet your specific requirements.

The Importance of Precision in Non-Standard Parts

When it comes to CNC non-standard metal parts machining, precision is paramount. Our state-of-the-art CNC machines can achieve tolerances as tight as ±.005mm, ensuring your custom parts fit perfectly in their intended applications.

Materials We Work With

Our expertise extends to various metals including aluminum, stainless steel, brass, copper, and titanium. Each material requires specific machining approaches, and our technicians have the knowledge to select the optimal parameters for your non-standard metal parts.

Our CNC Machining Process

The process begins with CAD design, followed by CAM programming to create the tool paths. Our multi-axis CNC machines then execute the program with exceptional accuracy. We perform rigorous quality checks at every stage to ensure the final product meets your exact specifications.

Why Choose EMAR for Your Custom Needs

With years of experience in CNC machining, EMAR offers:

Custom solutions for complex geometries

Fast turnaround times without compromising quality

Competitive pricing for both prototype and production runs

Comprehensive quality control measures

Applications Across Industries

Our CNC non-standard metal parts serve various industries including aerospace, automotive, medical devices, and industrial equipment. Whatever your application, we can create the perfect custom component for your needs.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque