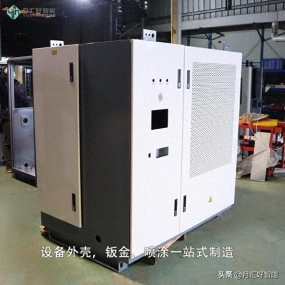

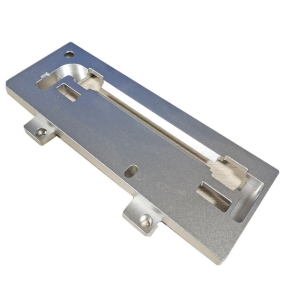

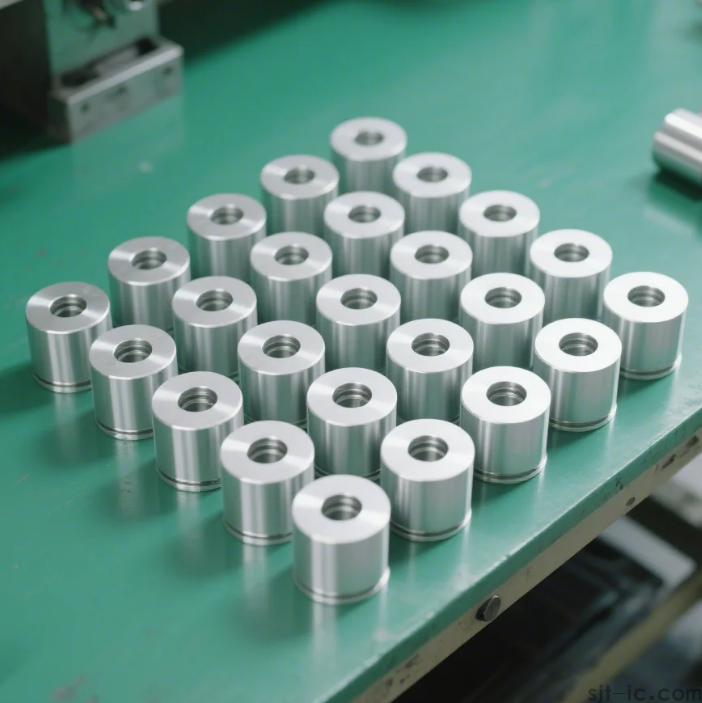

As a professional CNC small batch aluminum alloy machining service provider, EMAR Technology specializes in delivering high-precision components for prototyping and low-volume production. This article will explain the technical process and advantages of our aluminum machining solutions.

Understanding CNC Small Batch Aluminum Machining

CNC small batch aluminum alloy machining refers to the process of manufacturing limited quantities (typically 1-500 pieces) of aluminum components using computer-controlled milling and turning equipment. This approach combines the benefits of CNC precision with the flexibility of low-volume production, making it ideal for R&D departments and businesses requiring customized parts.

Key Advantages of Our Service

1. Rapid Turnaround: Our optimized workflow ensures 3-7 day delivery for most small batch orders

2. Material Expertise: We machine all aluminum grades including 6061, 7075, and 2024

3. Precision Guarantee: ±.005" tolerance standard with optional ±.001" for critical dimensions

4. Cost Efficiency: No mold investment required compared to mass production methods

Technical Process Overview

The CNC small batch aluminum alloy machining process at EMAR follows these stages:

1. CAD Model Analysis → 2. CNC Programming → 3. Fixture Design → 4. Machining Operations → 5. Quality Inspection → 6. Surface Treatment → 7. Final Packaging

Visit our official website at https://www.sjt-ic.com/ to learn more about our capabilities or request a free project evaluation. Our engineering team is ready to provide technical support for your specific aluminum machining requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque