Hey there, fellow engineers and procurement pros! 🛠️ Ever needed just 50 or 100 custom parts made, only to get a quote that made your budget scream? You're not alone. Figuring out the cost for small-batch CNC Machining can feel like a black box. This article cuts through the confusion and gives you a clear, behind-the-scenes look at how pricing *really* works for smaller orders.

🤔 So, What Drives the Price Tag Anyway?

It's not just about the material. Think of it like this: the cost is a puzzle with several pieces. First, there's the machine setup time. This is a fixed cost, whether you're making one part or a thousand. For small batches, this setup cost gets spread over fewer parts, which makes each individual part more expensive. Then there's programming time—someone has to tell the machine exactly what to do. The more complex your part, the longer this takes.

🧩 The Big Three: Time, Material, and... Surprises?

Let's break down the main cost drivers:

1. Machine Time & Setup: This is often the biggest chunk for small runs. The clock starts ticking from the moment the machine is set up for your job.

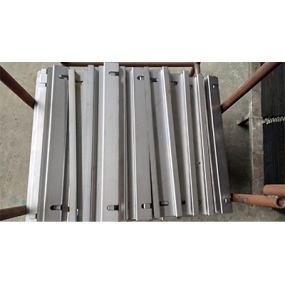

2. Raw Material Cost: Simple enough. A block of aluminum costs less than a block of titanium. But don't forget the material waste—chips left on the shop floor that you're also paying for.

3. Part Complexity & Design: Does your part have super deep holes, super thin walls, or super tight tolerances? These features can drastically increase the machining time and require special tools. Speaking of design, a DFM (Design for Manufacturability) review can sometimes spot tricky features early on. Though, to be totally honest, the specific savings from a DFM check can be hard to pin down until you actually get a quote.

💡 A Little Effort on Your End Can Save a Lot

You have more control than you think! Here's what you can do:

•Simplify Your Design: Fewer sharp internal corners, slightly relaxed tolerances where possible.

•Choose the Right Material: Don't specify a super-alloy if a common aluminum will do the job.

•Provide Clear, Complete Drawings: This reduces back-and-forth and prevents costly mistakes.

From my experience, I've seen projects where just modifying a single hard-to-machine feature cut the quote by 15%. It's always worth a second look!

💰 Let's Talk Real Numbers (Kind Of)

I wish I could give you a simple price-per-part, but it's impossible without a drawing. However, I can give you a rough idea of the cost structure. For a simple aluminum bracket in a batch of 50, the setup and programming cost might make up 40-60% of the total quote. The rest is material and machine time. If you then ordered 500 of the same bracket, the per-part cost would plummet because that setup cost is now divided 500 ways. This might suggest that larger batches are always cheaper. But wait a minute, what if you don't need 500 parts? Then you've got cash tied up in inventory. Sometimes, paying a bit more per part for a small batch is the smarter financial move.

🤝 How to Get the Best Quote for Your Project

Ready to get a price? Here's the playbook:

1.Prepare Your Files: Have a 3D model (like STEP) and a 2D drawing (PDF) ready.

2.Be Specific: Clearly state the material, quantity, surface finish, and any critical tolerances.

3.Shop Around (Wisely): Get quotes from a few different shops, but remember—the cheapest option isn't always the best. Look for clear communication and a willingness to answer your questions.

Ultimately, finding a reliable partner who understands your need for quality and clear pricing on smaller projects is worth its weight in gold. Hope this helps you on your next sourcing journey! 🚀

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque