Struggling to find a reliable shop for your aluminum parts? You're not alone. Many engineers and buyers hit a wall when they need high-precision aluminum CNC Machining but get quotes that are either too high or quality that's too low. 🤔 Where do you even start? This guide cuts through the noise, answering the big question: what should you really look for in an aluminum CNC machining partner?

What Exactly is Aluminum CNC Machining, Anyway?

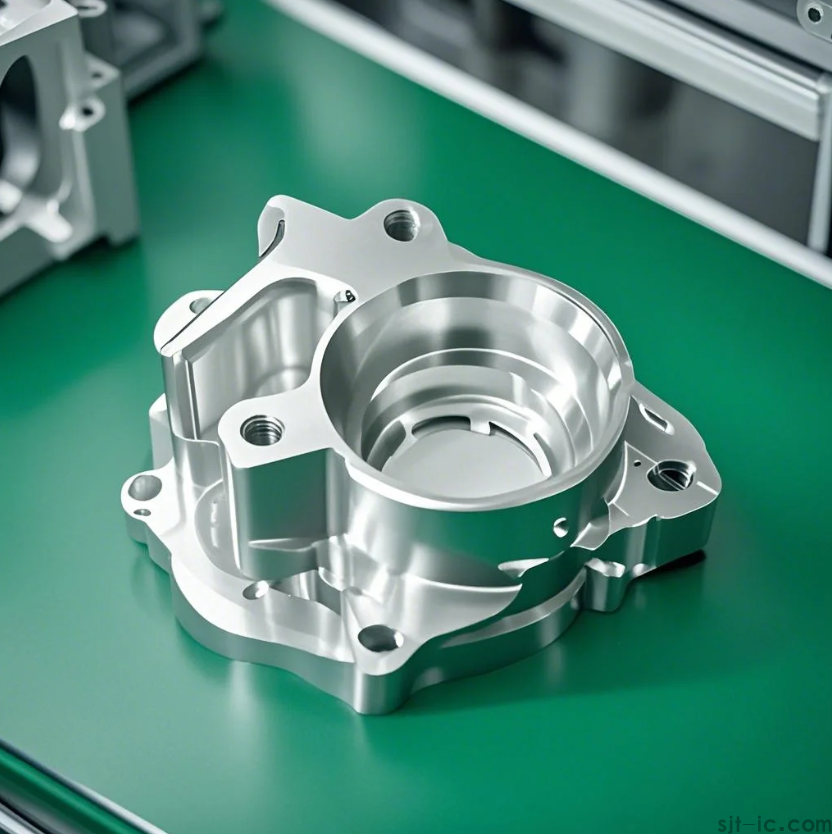

At its heart, it's a way to make complex metal parts by cutting away from a solid block of aluminum using computer-controlled tools. Think of it like a super-precise, automated sculptor. But it's not just about making shapes. The real magic happens in the details—the incredibly tight tolerances and smooth finishes that make your design work perfectly. I've seen projects turn from "meh" to magnificent just by getting this process right.

Why is Aluminum Such a Superstar for CNC?

Pretty much everyone loves working with aluminum, and for good reason. It's like the reliable friend of the metal world.

✅ Lightweight but Tough: It's strong without being heavy, which is a dream for things like drones or handheld devices.

✅ Easy to Machine: It cuts smoothly, which means faster production times and, often, lower costs for you.

✅ Resists Rust: It forms a protective layer, so it holds up well over time.

But here's the thing—not all aluminum is the same. Picking the right grade (like 6061 for general use or 7075 for super strength) is half the battle. A good partner will help you figure this out, not just take your order.

What Makes a CNC Shop "Precision"?

When shops throw around the word "precision," what does it actually mean for your parts? In my experience, it boils down to a few key things.

• Tight Tolerances: This is about how much a dimension can vary. A true precision shop can reliably hold tolerances within a few thousandths of an inch.

• Surface Finish: The part shouldn't just be the right shape; it should feel right. A great finish can be the difference between a prototype and a product-ready part.

• Consistency: Can they make part #1 identical to part #100? That's the real test.

However, it's worth asking if you really need the tightest possible tolerance on every single feature. Sometimes, specifying that drives up the cost and time for no real benefit. A trustworthy shop will point this out to you.

Beyond the Machine: Picking the Right Partner

The best CNC machine in the world is only as good as the people running it. So, how do you choose? Look beyond the equipment list.

🔧 Communication is Key: Do they answer your questions clearly and quickly? I can't stress this enough. A partner that communicates well from the start usually does so throughout the project.

🔧 Experience with Your Industry: A shop that's made bicycle parts might not understand the needs of a medical device. Their experience can save you from costly mistakes.

🔧 Willingness to Collaborate: The best outcomes I've seen come from a back-and-forth. They should offer suggestions to make your design more manufacturable or cost-effective.

Sometimes a smaller, more focused shop can give you better service than a giant factory. It's not always about scale; it's about attention to detail.

Okay, I'm Convinced. What's the Next Step?

You've got the knowledge. Now, it's time to take action. If you're tired of guessing and want a partner who treats your project with the care it deserves, the next logical step is to start a conversation.

Reach out to our team today for a no-obligation quote and design review. We're here to help you figure it out, not just sell you a service. Let's get your project moving. 🚀

From my desk: I've noticed that the most successful projects often come from a simple change—viewing the machining shop not as a vendor, but as an extension of your own team. That shift in mindset can open up a level of collaboration and results that simply sending out a drawing never will.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque