Hey there, fellow engineers and procurement managers! 👋 Ever been handed a complex, one-of-a-kind part design and felt that sinking feeling when you realize your usual suppliers aren't a good fit? You're not alone. Sourcing for non-standard parts, especially in small batches, is a whole different ball game. The process can feel like a maze, and picking the wrong CNC Machining factory can lead to delays, cost overruns, and headaches. So, how do you navigate this? Let's break it down together.

🤔 Why Can't I Just Use Any Machine Shop?

This is the first question that pops up. Standard parts are like buying off-the-rack suits – they mostly fit. Non-standard parts are bespoke tailoring. They require a shop that thrives on custom projects, not just repetitive production. A factory used to high-volume orders might struggle with the setup and programming nuances of your unique, low-volume project. The focus shifts from speed to precision and flexibility.

🔍 The Big Three: What to Really Look For

Forget just comparing prices. When evaluating a potential partner, these three areas are your golden ticket.

1. Communication is King (No, Seriously):

Can they understand your technical drawings? Do they ask smart questions? A good shop will talk to you about design for manufacturability (DFM) – suggesting small tweaks that make the part easier to machine without compromising its function. If they just nod and say "yes" to everything, that's a red flag. 🚩

2. Peek at Their Past Work (Portfolio Power):

Ask for case studies or examples of similar complex parts they've handled. This isn't about snooping; it's about verifying their capability. Look for diversity in materials and complexity. It might suggest they have the problem-solving skills you need.

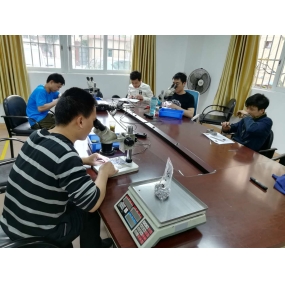

3. The Quality Control Puzzle:

Inquire about their quality control process. Do they do first-article inspections? What measuring tools do they use? A professional shop will be transparent about their steps to ensure every part meets your specs. The exact statistical methods they use for batch sampling, however, is an area I'm less familiar with – that's something you might want to ask them directly.

💸 Understanding the Quote: It's Not Just a Number

When you get a quotation, it should be a breakdown, not a single figure. A transparent quote helps you understand what you're paying for.

- Material Cost: The raw metal or plastic.

- Programming & Setup Time: This is often higher for one-off parts.

- Machining Time: How long the CNC machine will run.

- Secondary Finishing: Things like anodizing or sandblasting.

If a quote seems too good to be true, it probably is. They might be cutting corners on something crucial. However, it must be said, sometimes a slightly higher quote from a more communicative factory is cheaper in the long run by avoiding reworks.

🚀 Making the Final Decision: Trust Your Gut

You've done your homework. You've compared a few shops. Now what? Beyond the checkboxes, consider the rapport. Do you feel like they are a partner or just a vendor? I always lean towards the shop that seems genuinely interested in my project's success, even if they're not the absolute cheapest. That collaborative spirit is invaluable when unexpected issues pop up – and they often do with custom work. This approach has saved my projects more times than I can count.

So, there you have it. Choosing a small-batch CNC partner is less about finding a machine operator and more about finding a problem-solving ally. Hope this guide helps you make a confident choice on your next project! 💪

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque