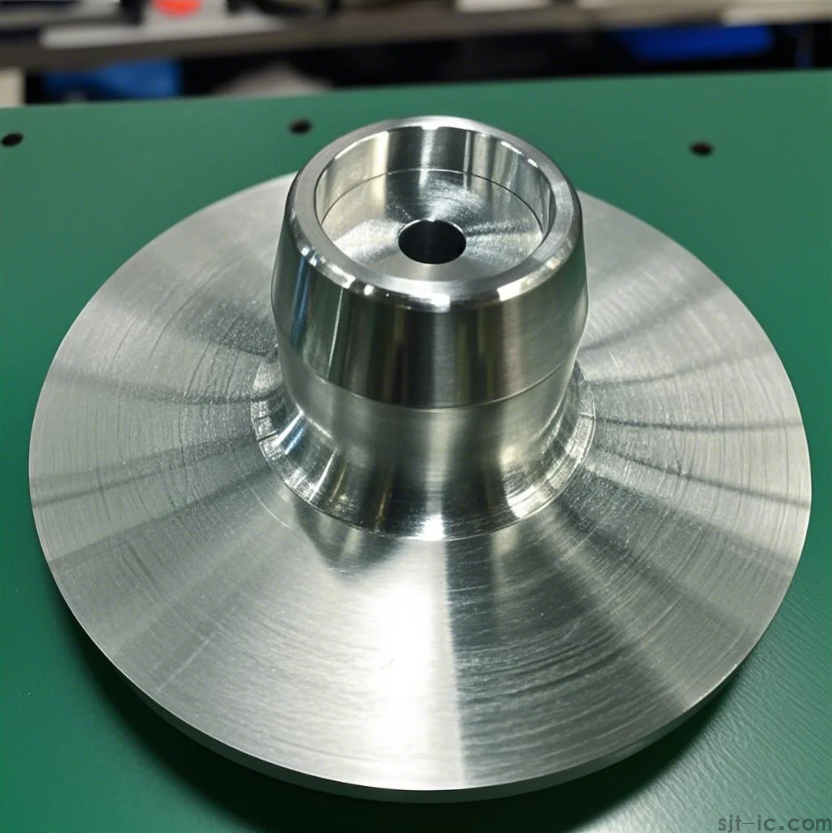

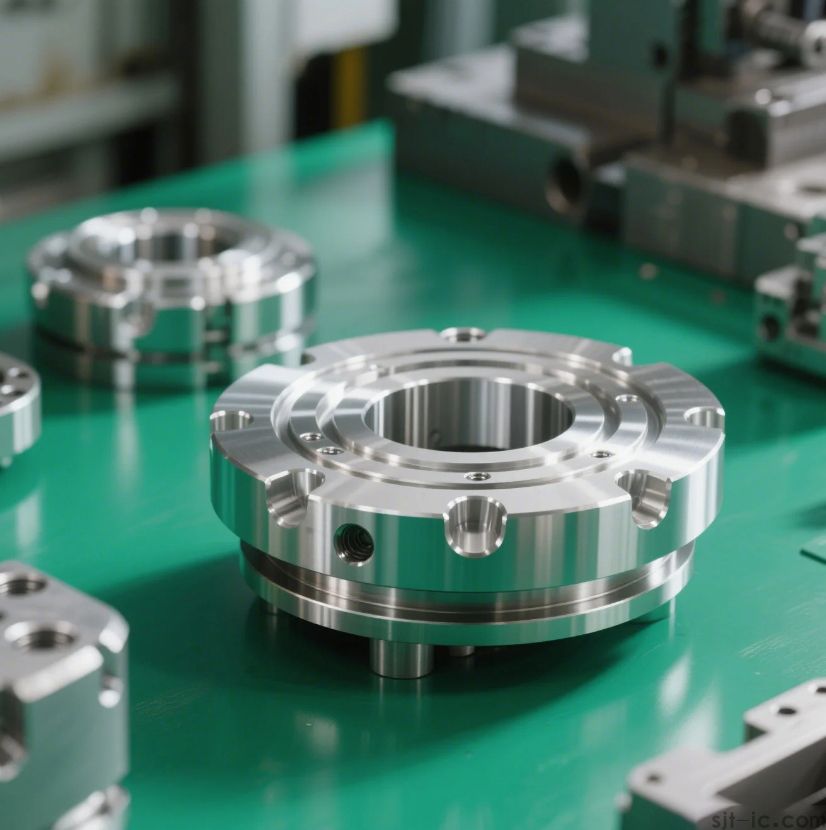

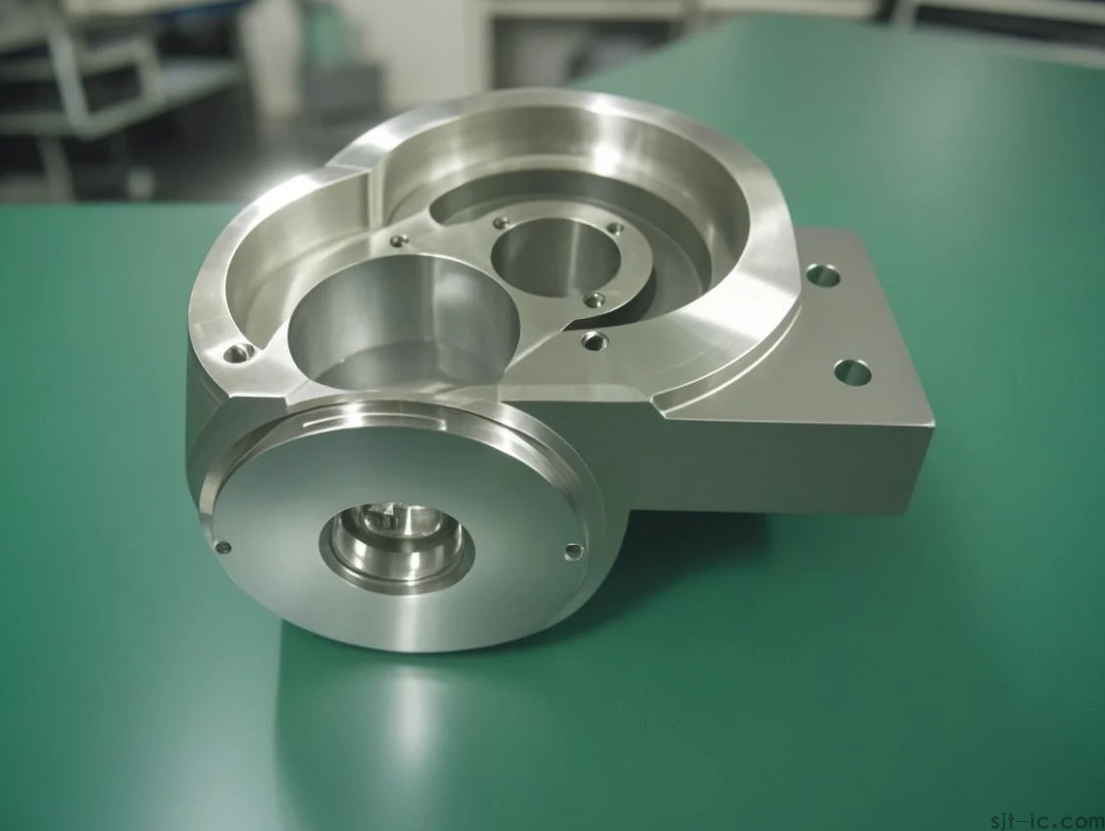

Hey there, fellow engineers and procurement pros! 👋 Ever feel that sinking feeling when a batch of CNC parts arrives, and they're just... off? The tolerances are a hair too wide, the surface finish is rough, and your production line is now on hold. Finding a manufacturer who gets "precision" right, consistently, is the real challenge. It's not just about finding any CNC shop; it's about finding a reliable precision CNC parts manufacturer that acts as an extension of your own quality team. So, how do you separate the best from the rest? Let's dive in and unpack this together! 🛠️

What Exactly Makes a CNC Manufacturer "Precision"?

First things first, let's get on the same page about "precision." It's more than just a buzzword. In the world of CNC parts manufacturing, precision means a few key things:

• Hitting Those Tiny Tolerances: We're talking about measurements within a few microns. A true precision shop can reliably hold tolerances like ±.025mm or even tighter for critical features.

• Mirror-Like Surface Finishes: It’s not just about the shape, but the smoothness. A great finish can reduce friction and improve the part's life.

• Doing It Every Single Time: Any shop can get lucky once. Precision is about repeatability across a production run of 10 or 10,000 parts.

Honestly, the specific equipment needed can vary a lot depending on the material and part geometry. I'm not a machine expert, but I know that the proof is always in the final part they deliver to you.

Key Questions to Grill Your Potential Manufacturer With 🔥

Don't be shy! Asking the right questions upfront saves headaches later. Here’s what I always ask:

• "Can you walk me through your quality control process from start to finish?" Listen for details about in-process checks and final inspection reports.

• "What measuring equipment do you use, and how often is it calibrated?" Tools like CMMs and optical comparators are a good sign.

• "Can you show me examples of similar complex or high-tolerance parts you've made?" A solid portfolio is worth a thousand sales pitches.

Asking these questions does more than just get you answers; it shows the manufacturer that you're a serious buyer who cares about quality.

Look Beyond the Price Tag: The Real Value of a Partnership

We all have budgets to manage, I get it. But choosing a CNC parts manufacturer based solely on the lowest quote is a classic and costly mistake. A rock-bottom price might indicate corners are being cut on material quality, machine maintenance, or that crucial quality control step. A slightly higher price from a reputable shop often includes invaluable peace of mind, on-time delivery, and clear communication. This might suggest that you're not just buying a part; you're investing in a smooth production flow and a reliable supply chain.

Communication: The Make-or-Break Factor Nobody Talks About Enough

Here's a personal insight: the best technical partners I've worked with weren't always the ones with the fanciest websites. They were the ones who answered emails promptly, were upfront about potential challenges, and treated my project like it was their own. Think about it. When a delay is inevitable, would you rather hear about it a week in advance from a communicative project manager, or be left in the dark until the delivery day? Clear and proactive communication is a non-negotiable trait of a reliable manufacturer. It’s the glue that holds the entire project together. However, it's worth noting that the internal workflow that makes a manufacturer responsive is a bit of a black box to us as customers.

My Final Two Cents: Start Small, Think Big

My go-to strategy for vetting a new precision parts manufacturer is to start with a small, non-critical order. Use this as a live test. How is their quoting process? How do they handle design feedback? What's the packaging like? Is the quality documentation clear? This low-risk trial run tells you everything you need to know about how they'll perform on your bigger, more important projects. Building a trusted manufacturing partnership takes time, but it all starts with that first, well-vetted step.

Hopefully, this guide helps you navigate your search with more confidence! What's the biggest hurdle you've faced when sourcing CNC parts? I'd love to hear about your experiences.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque