Hey there, fellow engineers and procurement pros! 😤 Ever been stuck between needing a few hundred custom metal parts and the nightmare of massive minimum order quantities? You know the drill – you get a brilliant design, but traditional manufacturers just shrug when you mention small batches. It's frustrating, right? Well, what if I told you there's a smarter way? Let's dive into the world of small batch CNC turning services, a game-changer for prototyping and limited production runs.

What Exactly Are Small Batch CNC Turning Services? 🤔

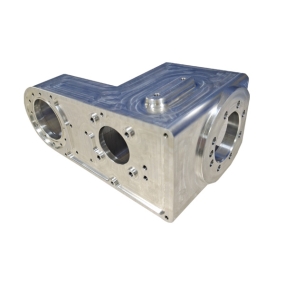

Simply put, it's getting precisely machined round parts made in quantities that don't break the bank or fill your warehouse. We're talking about orders from as low as 50 pieces up to maybe 1,000. Unlike mass production, the focus here is on flexibility, speed, and cost-effectiveness for smaller needs. It's perfect for when you're testing a new product, need replacement components, or have a specialized project that doesn't require thousands of units.

Why Would You Even Consider Small Batches? 💡

I get it, the per-part cost can be higher than mass production. But look at the bigger picture! First off, your initial cash outlay is much lower. You're not tying up a huge amount of capital in inventory. Secondly, it drastically cuts down on risk. What if your design has a flaw? With a small batch, you can test, get feedback, and make tweaks without a huge financial loss. It's all about being agile. However, it's worth mentioning that the specific cost-breakdown between, say, 100 units and 500 units can sometimes be less straightforward than it seems, and the per-part price doesn't always drop evenly.

How Does The Whole Process Work? (Step-by-Step) 🔧

It's pretty straightforward, but knowing the steps helps you manage the project better.

- Step 1: You Send Your Design. This is usually a 3D CAD file or a detailed drawing. The more clear it is, the smoother things go.

- Step 2: They Review and Quote. The shop looks at your design, material choice, and quantity, then gives you a price and timeline.

- Step 3: Programming & Setup. This is where the magic starts. A programmer creates the instructions for the CNC machine. This setup time is a key part of the cost for small runs.

- Step 4: Machining & Quality Checks. The machine does its work, and parts are regularly checked to ensure they match your specs perfectly.

Step 5: Delivery. Finished parts are shipped right to your door. Easy!

What About The Cost? Let's Be Real. 💰

This is the big question. The cost isn't just about the number of parts. It's a mix of:

Material (e.g., aluminum is different from stainless steel),

Part Complexity (more features = more machine time),

Quantity (obviously!), and

Surface Finishing (like anodizing or plating).

From my experience, the best way to get a good deal is to be open about your budget and ask if there are any design tweaks that could save money without hurting performance. Sometimes a tiny change can lead to big savings. This approach often proves... or perhaps just suggests that collaboration is better than just shopping for the lowest price.

How to Pick The Right Service Provider 🎯

Not all machine shops are created equal, especially for smaller jobs. Here’s what I usually look for:

- Do they actually welcome small orders? Some shops say they do, but you can tell it's not their focus.

- Check their equipment and expertise. Do they have the right machines for the materials you need?

Communication is key! You want a partner who answers your emails quickly and is transparent about the process. I've found that a shop's responsiveness during the quoting phase is a pretty good indicator of their service later on. Although, to be completely honest, the exact correlation between communication style and final part quality is something I'm still figuring out – it's not always a perfect match.

A Little Secret From My Side of The Fence 🤫

Many people get hung up on the machine brand a shop uses. But here's the thing: a skilled machinist and programmer are often more important than the machine itself. A great team on an older machine can produce better parts than a mediocre team on the latest model. Focus on the people and their proven work. That said, modern machines are fantastic for speed and repeatability, so it's a balance. But anyway, the real value lies in finding a supplier that feels like an extension of your own team.

Just last quarter, by using a dedicated small-batch service for our prototype components, we managed to cut our development time by almost one weeks. The data from that project was invaluable.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque