Hey there, are you a purchasing manager or engineer feeling stuck when you need a handful of small, precision stainless steel parts? 😥 You know, the ones that are crucial for your prototype or that limited production run. Maybe you've reached out to a few shops only to hear they're too busy with massive orders, or the quote they gave you made your eyes water. Sound familiar? This is a common pain point, but the good news is, specialized CNC Machining for small parts is absolutely a thing. Let's dive into how you can navigate this field like a pro. 🚀

What Exactly is "Small Parts" CNC Machining, Anyway?

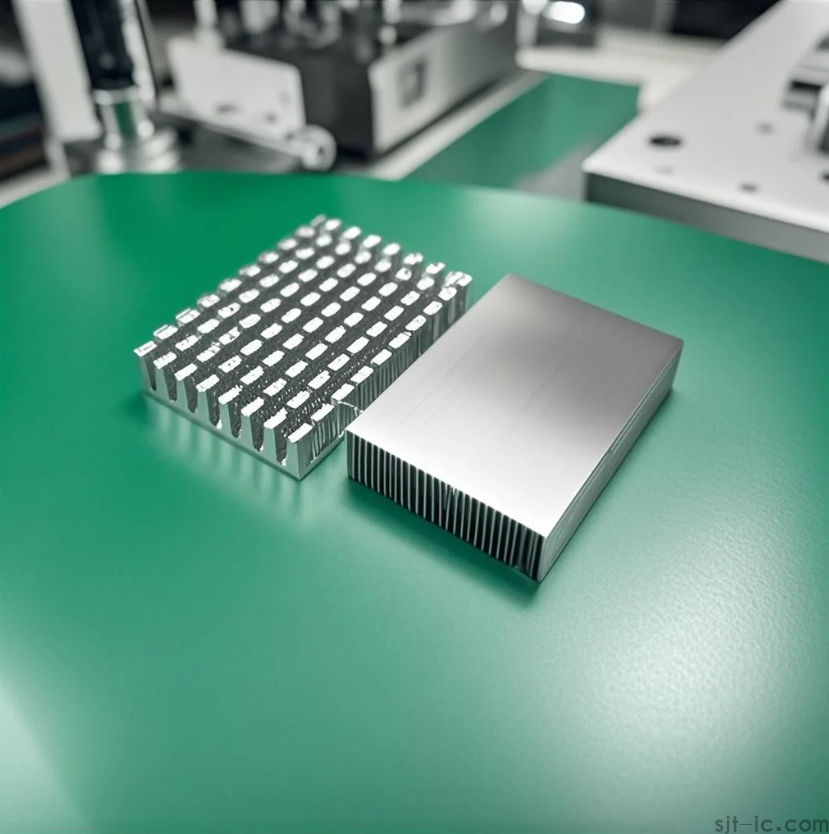

When we talk about "small parts" in the CNC world, we're generally referring to components that could fit in the palm of your hand, often with intricate features and tight tolerances. Think everything from tiny medical device components and specialized electronic housings to custom screws and miniature mechanical linkages. The challenge here isn't just about making something small; it's about maintaining incredible accuracy and a perfect surface finish on a tough material like stainless steel. This requires specific machine tools, skilled operators, and a keen eye for detail.

Why is Machining Small Stainless Parts So Tricky? 🤔

Stainless steel is a fantastic material—strong, corrosion-resistant, and durable. But those same qualities make it a beast to machine, especially when the part is tiny.

• Tool Pressure and Breakage: When your cutting tool touches the metal, it pushes against it. On a small, delicate part, this pressure can cause bending, vibration, or even break the part—or the tool itself.

• Heat is the Enemy: Machining generates heat. In a small part, this heat has nowhere to go, which can warp the metal or ruin its temper. We have to be super careful with cooling.

• Chip Control: Those little metal shavings, or "chips," can get stuck in the machining path, scratching the finely finished surface. Managing this is an art form.

So, while the basic principles of CNC are the same, the execution for miniaturized components is a different ball game. The specific setup to perfectly manage toolpaths for these tiny geometries is something I'm still trying to fully wrap my head around.

How to Choose the RIGHT Manufacturer for Your Small Batch

Not every machine shop is equipped or willing to take on small-part projects. Here’s what you should be looking out for:

• Ask About Their Specialty: Don't be shy! Straight up ask if they regularly handle small-batch, high-precision work. A shop that lives and breathes this will show you examples.

• Check Their Equipment: Look for shops with high-speed CNC mills and lathes. These machines are designed for the high spindle speeds and quick movements needed for fine details.

• Gauge Their Communication: The best shops will ask a lot of questions about your application, tolerances, and finish requirements. If they don't, that's a red flag. 🚩

From my experience, the shops that excel in this niche are often the ones that act more like engineering partners than just order-takers.

Getting the Best Results: A Few Pro Tips

To make your project a success and avoid headaches, keep these points in mind when you're designing and planning:

• Design for Manufacturability (DFM): Seriously, talk to your manufacturer early. A tiny change to a corner radius or an internal wall thickness can make the part infinitely easier and cheaper to produce.

• Be Realistic About Tolerances: Chasing a tolerance of ±.01mm when ±.05mm will do the job might triple your cost. Specify only the critical tolerances.

• Discuss Finishes Early: Do you need a matte, brushed look or a mirror high-gloss finish? This affects the machining process and cost, so it's not just an afterthought.

Perhaps the most underrated tip is to provide a clear, clean 3D model (like a .STEP file) along with your 2D drawings. This eliminates guesswork and prevents errors.

Wrapping It Up: It's All About Partnership

Finding a reliable partner for your small stainless steel CNC machining needs doesn't have to be a nightmare. It boils down to finding a specialist who communicates well and understands the unique challenges of working at a smaller scale. The right manufacturer won't just make your parts; they'll help you perfect them. I've seen projects turn from "impossible" to "flawless" simply by having the right conversations upfront. Remember, the cheapest quote is rarely the most cost-effective solution in the long run. Investing in a quality partnership pays off with reliable parts, fewer delays, and a whole lot less stress. 😊

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque