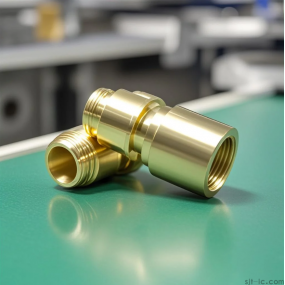

Understanding Brass Precision CNC Machining

Brass precision CNC machining is a specialized manufacturing process that combines computer numerical control technology with the unique properties of brass alloys. This method delivers exceptional dimensional accuracy, typically within ±.005mm, making it ideal for components requiring tight tolerances. The process begins with high-quality brass rods or billets, which are then transformed into complex geometries through milling, turning, or drilling operations.

Why Choose Brass for CNC Machining?

Brass offers several advantages for precision components: excellent machinability (rated 100% compared to 20% for steel), natural corrosion resistance, good electrical conductivity, and antimicrobial properties. These characteristics make it perfect for mass production of electrical connectors, plumbing fittings, musical instruments, and decorative hardware. At EMAR, we utilize C36000 (free-cutting brass) for optimal surface finish and tool life.

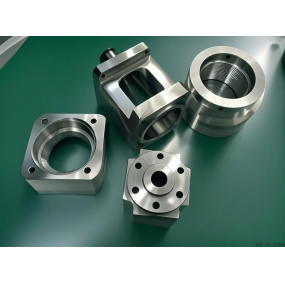

Our Mass Production Capabilities

EMAR's advanced CNC workshops feature 25 multi-axis machining centers capable of handling production runs from 1,000 to 100,000+ units. Our CNC mechanical batch processing system includes automated loading/unloading, in-process gauging, and statistical process control to maintain consistency across large volumes. Typical lead times for brass components range from 2-4 weeks depending on complexity and quantity.

Quality Assurance in Brass CNC Machining

Every batch undergoes rigorous inspection including CMM measurements (.001mm resolution), surface roughness testing, and material composition verification. We maintain ISO 9001:2015 certification and provide full material traceability with mill test reports. Our defect rate remains below .2% through preventive maintenance and tool wear monitoring systems.

Cost Optimization for Large Orders

For mass production projects, we implement several cost-saving measures: optimized nesting to reduce material waste (achieving 92% utilization), high-speed machining strategies, and dedicated tooling setups. Clients ordering 10,000+ units typically benefit from 15-30% cost reductions through economies of scale. Contact our engineering team for a customized brass machining solution that meets your technical and budgetary requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque