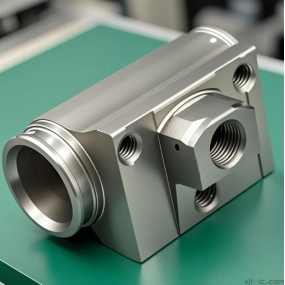

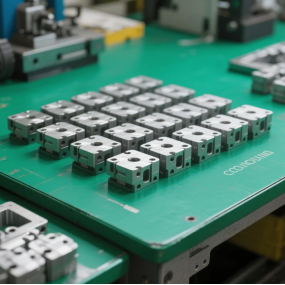

As a leading provider of **CNC Machining parts customization**, EMAR delivers precision-engineered solutions for industries ranging from aerospace to automotive. Our advanced CNC technology ensures tight tolerances (±.005mm), material versatility (aluminum, stainless steel, titanium), and scalable production from prototypes to bulk orders.

Why Choose EMAR for Your Custom CNC Parts?

1. End-to-End Capabilities: From CAD/CAM design to post-processing (anodizing, powder coating), we handle every step in-house.

2. Industry-Specific Expertise: Specialized in complex geometries for medical implants, automotive **CNC components**, and robotics.

3. Rapid Turnaround: 3-5 day standard lead time with 24/7 quality monitoring.

Our CNC Machining Process

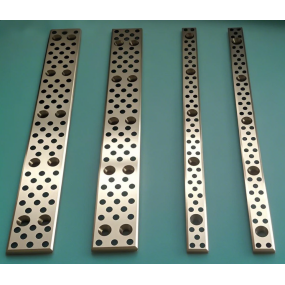

1. Material Selection: 6061-T6 aluminum, 304/316 stainless steel, PEEK, and more.

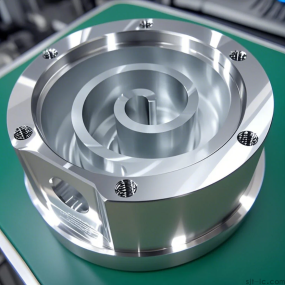

2. 5-Axis Precision: Simultaneous machining reduces errors and improves surface finish (Ra .8μm achievable).

3. Quality Assurance: ISO 9001-certified inspections with CMM and optical comparators.

Applications of Custom CNC Parts

EMAR’s **CNC machined components** are critical for:

- Electronics: Heat sinks with micro-channels

- Energy: Turbine blades with aerodynamic profiles

- Medical: FDA-compliant surgical instruments

Request a free DFM analysis today at www.sjt-ic.com to optimize your design for manufacturability and cost-efficiency.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque