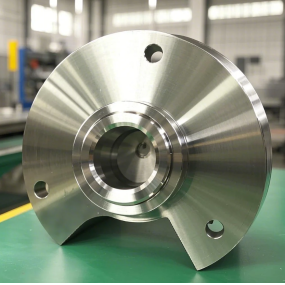

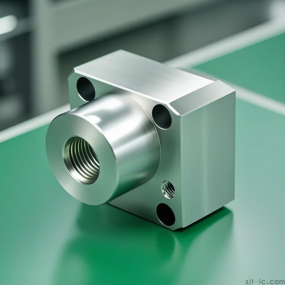

As a leading CNC precision small parts machining specialist, EMAR Technology delivers exceptional manufacturing solutions for industries requiring micron-level accuracy and complex geometries.

The Critical Importance of Precision in Small Parts Machining

When it comes to CNC precision small parts machining, dimensional accuracy and surface finish quality are paramount. Our 5-axis CNC machines achieve tolerances as tight as ±.005mm, ensuring perfect fit and function for medical components, aerospace fasteners, and electronic enclosures.

Advanced Capabilities for Complex Components

EMAR's machining center features:

High-speed spindles (up to 50,000 RPM)

Micro-tooling capabilities (down to .1mm diameter)

In-process measurement systems

Swiss-type lathes for complex turned parts

Material Expertise for Demanding Applications

We specialize in machining challenging materials for CNC precision small parts including titanium alloys, medical-grade plastics, and hardened steels. Our engineers optimize cutting parameters for each material to ensure optimal tool life and surface integrity.

Quality Assurance Protocol

Every component undergoes rigorous inspection:

First-article inspection with CMM

Statistical process control monitoring

Surface roughness measurement

100% final dimensional verification

Visit EMAR Technology to request a quote for your precision machining project or consult with our engineering team about your specific requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque