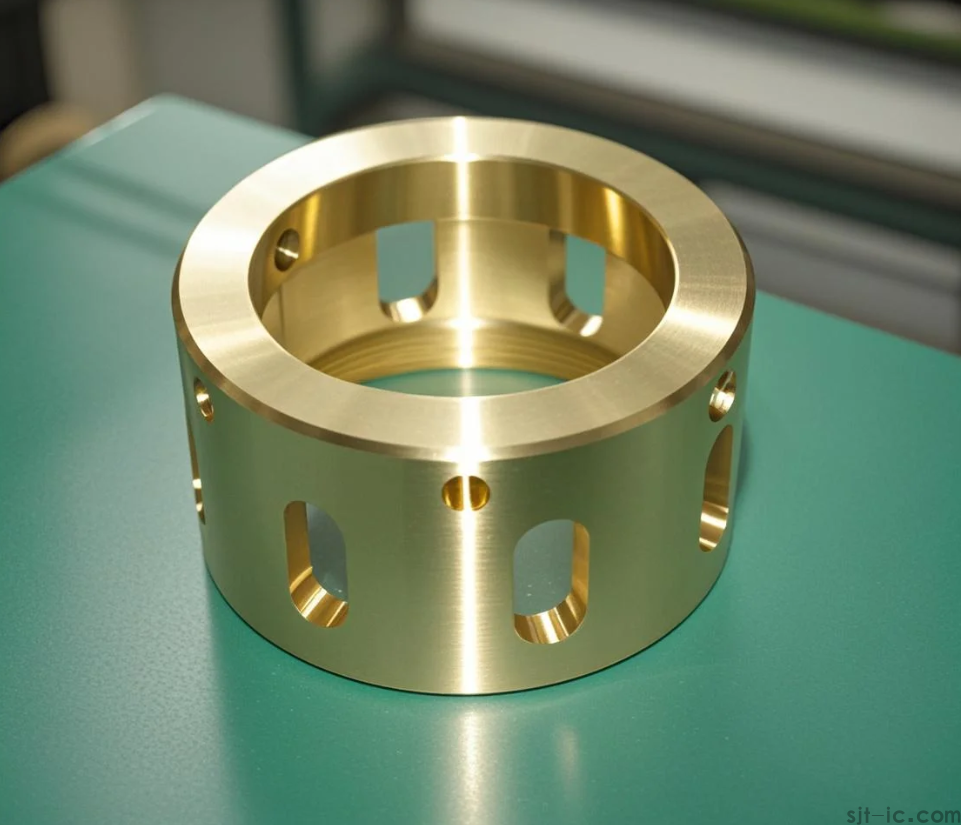

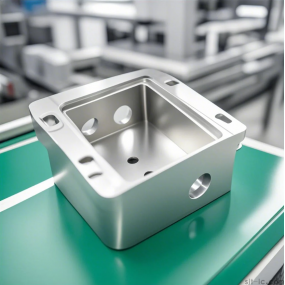

Copper Parts CNC Precision Machining Factory

As a leading copper parts CNC precision machining factory, EMAR specializes in delivering high-quality machined copper components for various industries. Our advanced CNC technology and skilled technicians ensure exceptional precision and surface finishes for all your copper part requirements.

Why Choose Our Copper CNC Machining Services?

Copper presents unique machining challenges due to its softness and thermal conductivity. Our factory has developed specialized processes to overcome these challenges, including:

Customized tooling solutions to prevent material deformation

Optimized cutting parameters for superior surface finish

Precision cooling systems to maintain dimensional stability

Rigorous quality control at every production stage

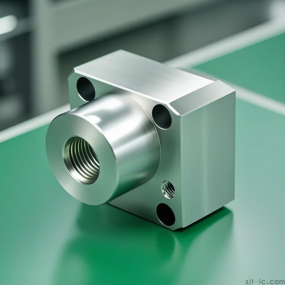

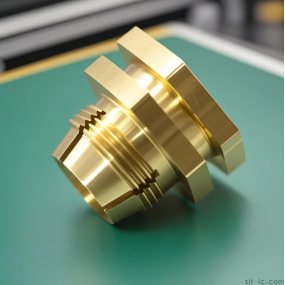

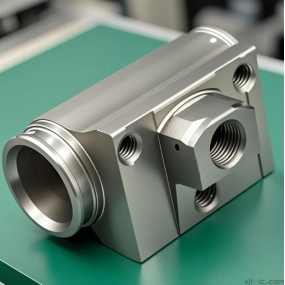

Our Copper CNC Machining Capabilities

EMAR's CNC precision machining facility handles all types of copper alloys, including pure copper, brass, and bronze. We offer:

Complex 3-5 axis milling and turning operations

Tolerance capabilities down to ±.005mm

Surface finishes as fine as Ra .2μm

Secondary operations including plating, polishing, and heat treatment

Applications of Precision Machined Copper Parts

Our copper parts serve critical functions across multiple industries:

Electrical components (busbars, connectors, terminals)

Heat exchangers and cooling systems

Plumbing fixtures and valves

Automotive and aerospace applications

Semiconductor manufacturing equipment

Quality Assurance at EMAR

Every copper part undergoes comprehensive inspection using:

Coordinate Measuring Machines (CMM)

Surface roughness testers

Electrical conductivity verification

Visual and dimensional inspections

As your trusted copper CNC machining partner, EMAR combines technical expertise with state-of-the-art equipment to deliver precision components that meet your exact specifications. Contact us today to discuss your project requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque