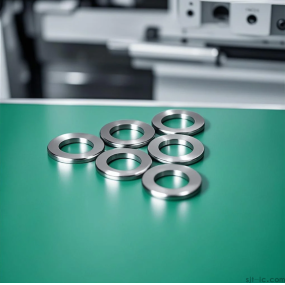

As a leading CNC marine parts machining specialist, EMAR Company delivers high-performance components that meet the stringent demands of maritime applications. Our advanced CNC technology ensures exceptional accuracy and repeatability for critical ship systems.

Why Choose CNC Machining for Marine Components?

The marine environment presents unique challenges including corrosion, vibration, and extreme pressures. Our CNC machining processes create parts with:

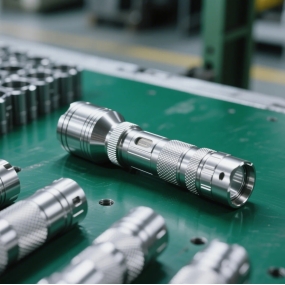

Tight tolerances (±.005mm) for propulsion systems

Superior surface finishes (Ra .8μm achievable)

Material integrity for saltwater resistance

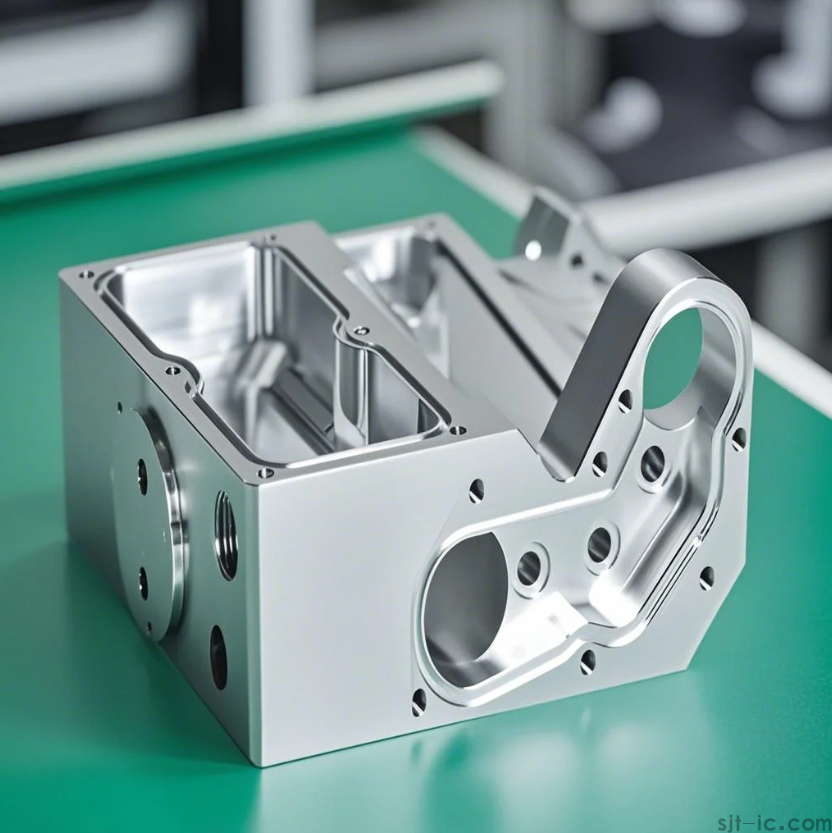

Complex geometries for hydraulic and steering systems

Our Marine Machining Capabilities

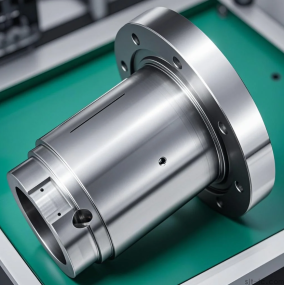

EMAR's 5-axis CNC centers produce:

Propeller shafts and rudder components

Engine mounting brackets

Deck machinery parts

Pump housings and valve bodies

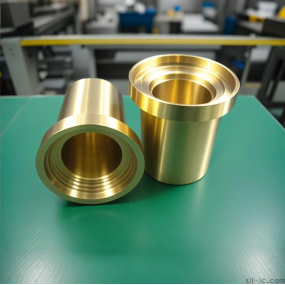

Material Expertise for Harsh Environments

We machine marine-grade materials including:

316L stainless steel

Bronze alloys (C95800, C95500)

Aluminum 5083/6061

Duplex and super duplex steels

With ISO 9001-certified CNC marine parts production and 15+ years of naval architecture experience, EMAR guarantees components that withstand IMO standards and classification society requirements. Our end-to-end service includes CAD/CAM programming, precision machining, and comprehensive quality inspection.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque