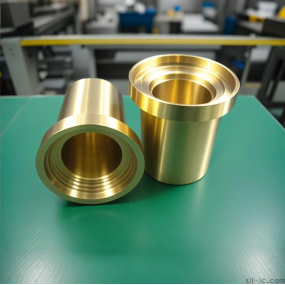

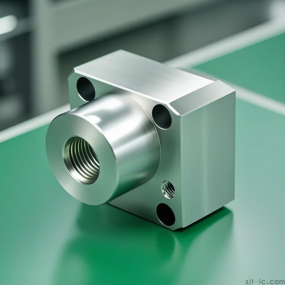

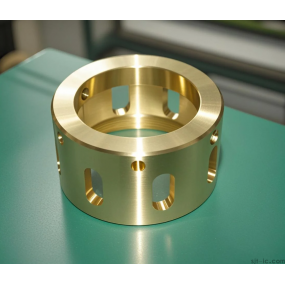

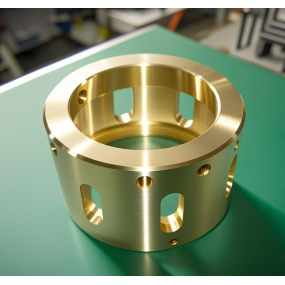

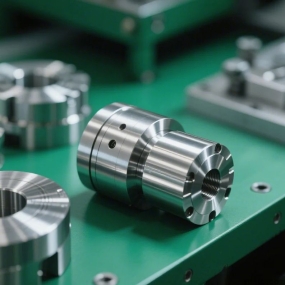

As a leading CNC Machining stainless steel parts provider, EMAR Company specializes in delivering precision-engineered components for industries ranging from aerospace to medical devices. This article explores the technical nuances and competitive advantages of our services.

Why Choose CNC for Stainless Steel Parts?

Stainless steel's high strength and corrosion resistance make it ideal for critical applications, but its hardness poses machining challenges. Our CNC machining solutions overcome these with:

Advanced toolpath programming to reduce tool wear

High-pressure coolant systems for thermal management

Rigidity-optimized machine tools (5-axis capability)

Key Process Stages

EMAR's certified workflow ensures dimensional accuracy within ±.01mm:

Material Certification: Verification of SS304/316/17-4PH grades

Fixturing Design: Custom workholding for complex geometries

Precision Machining: Multi-operation processing with in-process QC

Surface Enhancement: Optional passivation or electropolishing

Industry-Specific Applications

Our stainless steel components serve demanding sectors:

Medical: FDA-compliant surgical instrument parts

Food Processing: Hygienic-grade fittings with Ra≤.8μm

Energy: Corrosion-resistant valve bodies

EMAR's Competitive Edge

Beyond standard machining, we offer:

Material traceability documentation

Prototype-to-mass-production scalability

ISO 9001:2015 certified quality system

Explore our CNC capabilities for stainless steel at www.sjt-ic.com or request a DFM analysis today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque