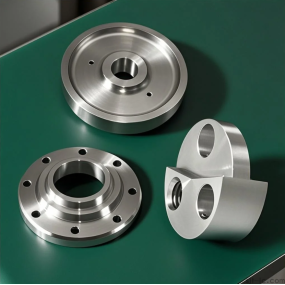

In industrial manufacturing, CNC Machining oversized parts presents unique challenges that require specialized expertise. As a leading CNC machining service provider, EMAR offers comprehensive solutions for large-scale components across aerospace, energy, and heavy equipment sectors.

Technical Challenges in Oversized Part Machining

Machining large workpieces (typically exceeding 2m in any dimension) demands:

Customized machine beds with extended travel ranges

Rigid fixturing systems to prevent vibration

Thermal compensation technology

Multi-axis synchronization capabilities

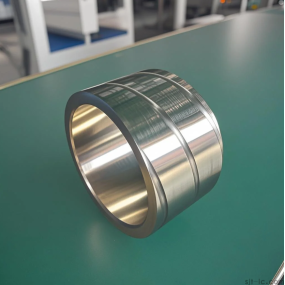

EMAR's Capabilities for Large-Scale Projects

Our facility features:

5-axis gantry mills with 8m x 4m x 3m capacity

High-torque spindles (50+ HP) for heavy cuts

Laser measurement systems for dimensional verification

On-machine probing for quality control

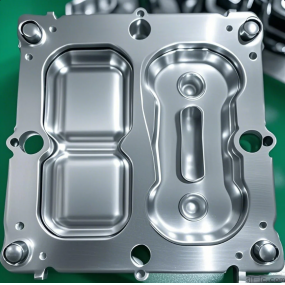

Material Considerations

We specialize in machining oversized parts from:

Aluminum alloys (6061, 7075)

Stainless steels (304, 316)

Titanium grades

Engineering plastics

Quality Assurance Protocol

Every large component undergoes:

In-process dimensional checks

Surface finish verification

Ultrasonic testing for critical applications

Final CMM inspection

With 15+ years of experience in large-part manufacturing, EMAR delivers precision CNC machining solutions that meet strict tolerances (±.1mm) even for massive components. Contact our engineering team at www.sjt-ic.com for project consultation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque