In the realm of high-performance turbine manufacturing, CNC Machining turbine components demands unparalleled precision and expertise. As a leading CNC machining service provider, EMAR delivers cutting-edge solutions for aerospace, energy, and industrial applications.

Why Choose CNC Machining for Turbine Components?

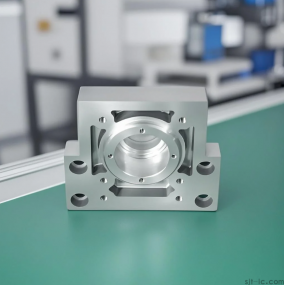

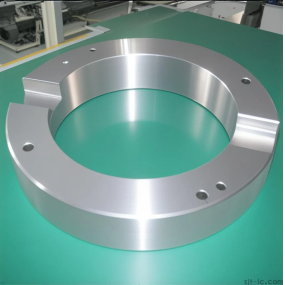

Turbines operate under extreme conditions requiring micron-level accuracy. Our 5-axis CNC machining centers produce complex geometries in heat-resistant alloys like Inconel and Titanium with ±.005mm tolerance. The automated process ensures repeatability for critical components like blades, rotors, and housings.

EMAR's Advanced Turbine Manufacturing Capabilities

Our 15,000㎡ facility features:

High-speed milling (24,000 RPM) for fine surface finishes

Swiss-type lathes for micro-precision shafts

EDM machining for intricate cooling channels

CMM inspection with 3D scanning

Material Expertise for Demanding Applications

We machine all turbine-grade materials including:

Nickel-based superalloys (Hastelloy, Waspaloy)

Maraging steels

Ceramic matrix composites

Aluminum alloys for prototypes

Quality Assurance Protocol

Every turbine component undergoes:

Raw material certification (AMS/MIL specs)

In-process dimensional checks

Surface roughness testing

Final load testing (for rotating assemblies)

With ISO 9001:2015 certification and AS910 compliance, EMAR guarantees aerospace-grade quality for your most challenging CNC machining turbine projects. Contact our engineering team at www.sjt-ic.com for technical consultation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque