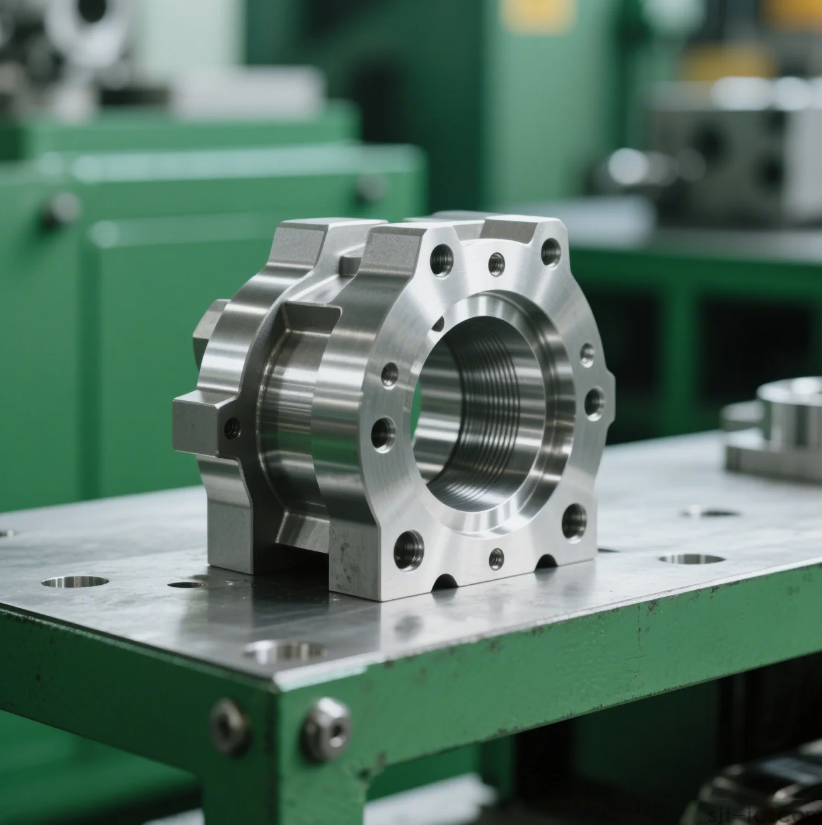

CNC Valve Machining: Precision Solutions for Industrial Applications

As a leading CNC valve machining specialist, EMAR Company delivers high-precision components for critical fluid control systems across industries. Our advanced CNC technology ensures unmatched accuracy in manufacturing valves that meet stringent industry standards.

Why Choose CNC Machining for Valve Production?

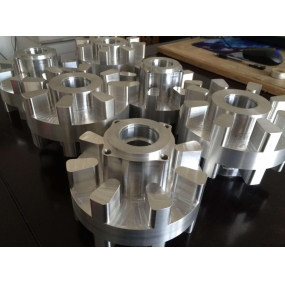

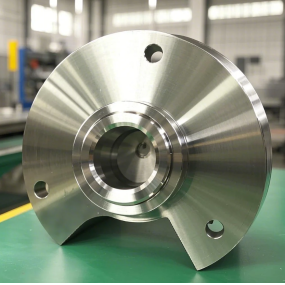

CNC valve machining offers superior dimensional accuracy and repeatability compared to conventional manufacturing methods. Our 5-axis CNC machines can produce complex valve geometries, including ball valves, gate valves, and butterfly valves, with tolerances as tight as ±.005mm. This precision directly translates to better sealing performance and longer service life.

Our CNC Valve Machining Capabilities

EMAR's manufacturing facility features state-of-the-art CNC turning and milling centers specifically configured for valve components. We work with various materials including:

Stainless steel (304, 316, 17-4PH)

Brass and bronze alloys

Titanium and nickel-based superalloys

Engineering plastics (PTFE, PEEK)

Quality Assurance in CNC Valve Machining

Every valve component undergoes rigorous inspection using coordinate measuring machines (CMM) and surface roughness testers. Our quality management system is ISO 9001 certified, ensuring consistent quality from prototype to mass production.

With EMAR's CNC machining expertise, you receive valve components that meet API, ASME, and other international standards. Our technical team can assist with design optimization for manufacturability and cost efficiency without compromising performance.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque