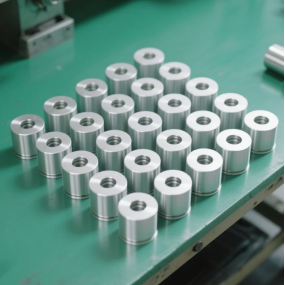

In modern manufacturing, 5-axis CNC Machining represents the pinnacle of precision and flexibility. This advanced technology enables the production of highly complex geometries with unmatched accuracy, making it indispensable for aerospace, medical, and automotive industries.

How 5-Axis CNC Machining Works

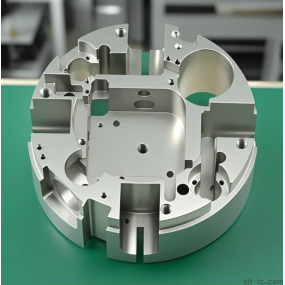

Unlike traditional 3-axis machines, 5-axis CNC systems simultaneously rotate the workpiece on two additional axes (A and B) while cutting. This allows the tool to approach the material from virtually any direction without repositioning, reducing setup time and improving dimensional consistency.

Key Advantages of 5-Axis Machining

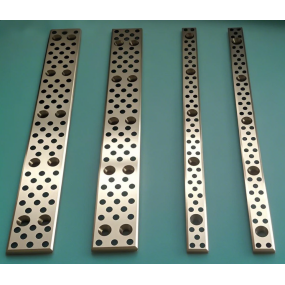

1. Single-Setup Precision: Eliminates multiple fixturing steps, reducing cumulative errors

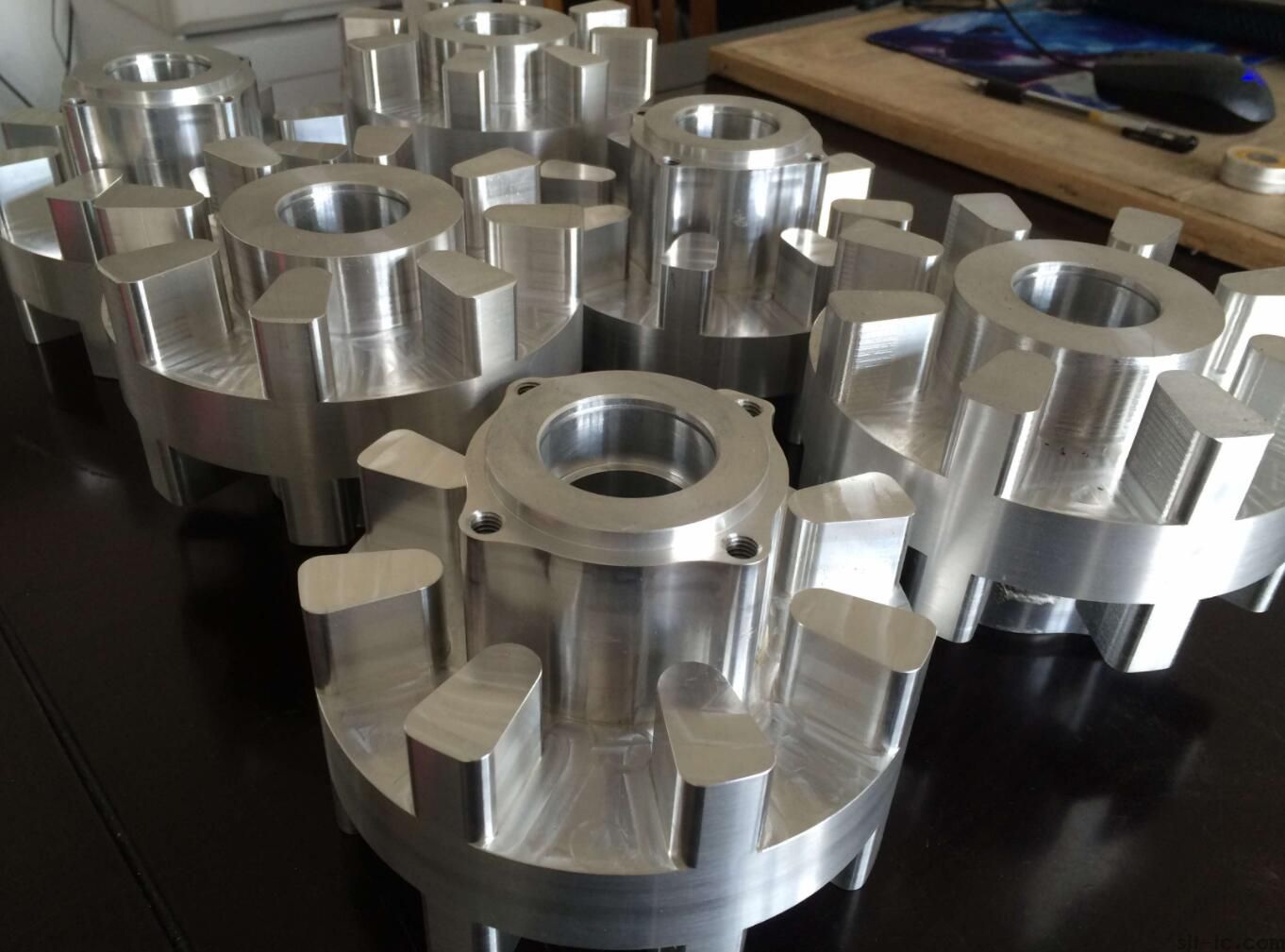

2. Complex Geometry Capability: Produces organic shapes impossible with 3-axis machines

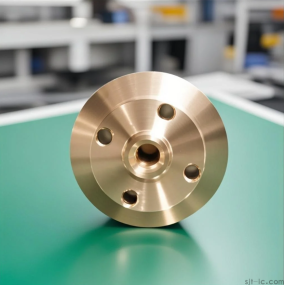

3. Improved Surface Finish: Optimal tool positioning minimizes visible tool marks

4. Faster Production: 30-50% time savings compared to multi-stage 3-axis processing

EMAR's 5-Axis Machining Expertise

At EMAR, our 5-axis CNC machining center features:

High-rigidity German-engineered spindles (20,000 RPM)

.005mm positional accuracy

Advanced toolpath optimization software

In-process measurement systems

We specialize in machining aerospace alloys, medical-grade titanium, and high-tolerance injection molds. Our engineers will collaborate with you to optimize designs for manufacturability while maintaining functional requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque