As a leading CNC connector machining specialist, EMAR delivers high-precision components for critical industrial connections. Our advanced CNC technology ensures dimensional accuracy and repeatability for connectors across aerospace, automotive, and electronics sectors.

What is CNC Connector Machining?

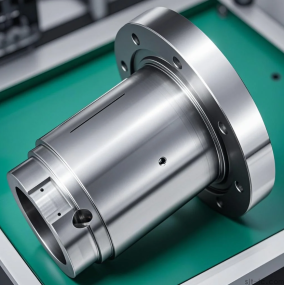

CNC connector machining refers to the computer-controlled manufacturing of mechanical connection components with tight tolerances (typically ±.005mm). These include electrical terminal blocks, hydraulic fittings, pneumatic couplings, and specialized interface components requiring flawless mating surfaces.

Key Advantages of Our CNC Connector Manufacturing

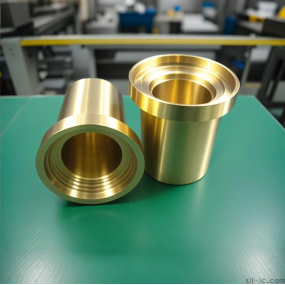

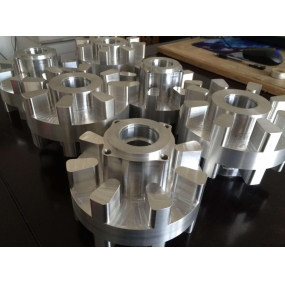

1. Material Versatility: Machining brass, aluminum, stainless steel (303/304/316), and engineering plastics

2. Surface Finish Excellence: Achieving Ra .8μm or better for sealing surfaces

3. Thread Precision: Producing UNF, metric, NPT, and custom threads with Go/No-Go gauge verification

4. Batch Consistency: Maintaining ±.01mm tolerance across production runs

EMAR's CNC Connector Machining Process Flow

Our certified workflow ensures connector reliability:

Material Certification → 2. CNC Turning/Milling → 3. Deburring → 4. Surface Treatment (Plating/Anodizing) → 5. 100% Dimensional Inspection → 6. Pressure Testing (for fluid connectors)

With ISO 9001-certified production and 15+ years of connector manufacturing experience, EMAR solves complex connection challenges through precision CNC Machining. Contact our engineers at www.sjt-ic.com for custom connector solutions.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque