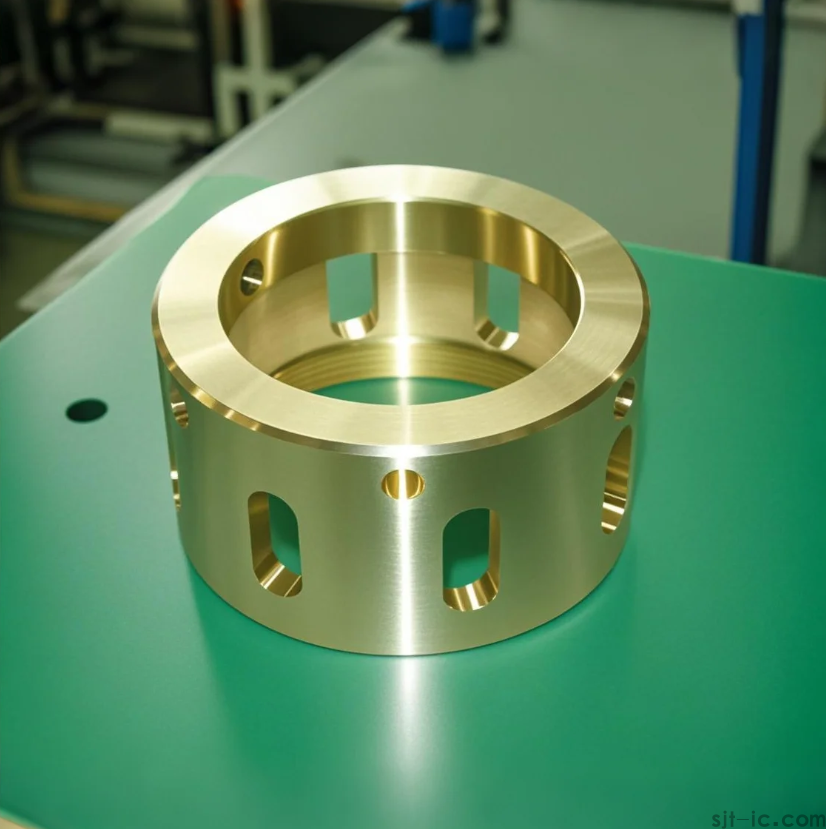

As a leading CNC Machining manufacturer, EMAR specializes in high-precision copper parts CNC machining for industries ranging from electronics to aerospace. Our advanced 5-axis CNC machines and ISO 9001-certified processes ensure exceptional dimensional accuracy and surface finishes for your custom copper components.

Why Choose CNC Machining for Copper Parts?

Copper's excellent electrical/thermal conductivity makes it ideal for heat exchangers, electrical contacts, and RF components. However, its softness and gummy nature require specialized CNC machining techniques. Our solutions include:

- Precision cooling systems to prevent workpiece deformation

- Optimized tool paths to minimize material adhesion

- Micro-machining capabilities (±.005mm tolerance)

- Post-processing options (electroplating, polishing, passivation)

Our Copper CNC Machining Capabilities

EMAR's 15,000㎡ facility features:

| Process | Specifications |

|---|---|

| Material Grades | C11000, C10100, C14500, C17200 |

| Machining Tolerance | ±.01mm (standard), ±.005mm (precision) |

| Surface Finish | Ra .4μm (mirror finish available) |

| Maximum Part Size | 800×500×300mm |

Industry-Specific Applications

We deliver copper CNC components for:

- Electronics: Busbars, waveguide components

- Automotive: Welding nozzles, bearing cages

- Medical: Electrosurgical electrodes, MRI components

- Energy: Heat sink plates, power distribution parts

Quality Assurance Process

Every copper part undergoes rigorous inspection:

- Material certification (Mill Test Reports)

- First-article inspection with CMM

- Conductivity testing (for electrical components)

- 100% dimensional verification for critical features

With 12+ years of experience in non-ferrous metal machining, EMAR provides DFM analysis, rapid prototyping, and low-to-high volume production. Submit your CAD files today for a free project evaluation at www.sjt-ic.com.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque