When precision meets regulatory compliance, medical device CNC Machining companies play a pivotal role in manufacturing life-saving equipment. At EMAR, we specialize in producing high-precision components that meet stringent medical industry standards.

Why Choose Specialized CNC Machining for Medical Devices?

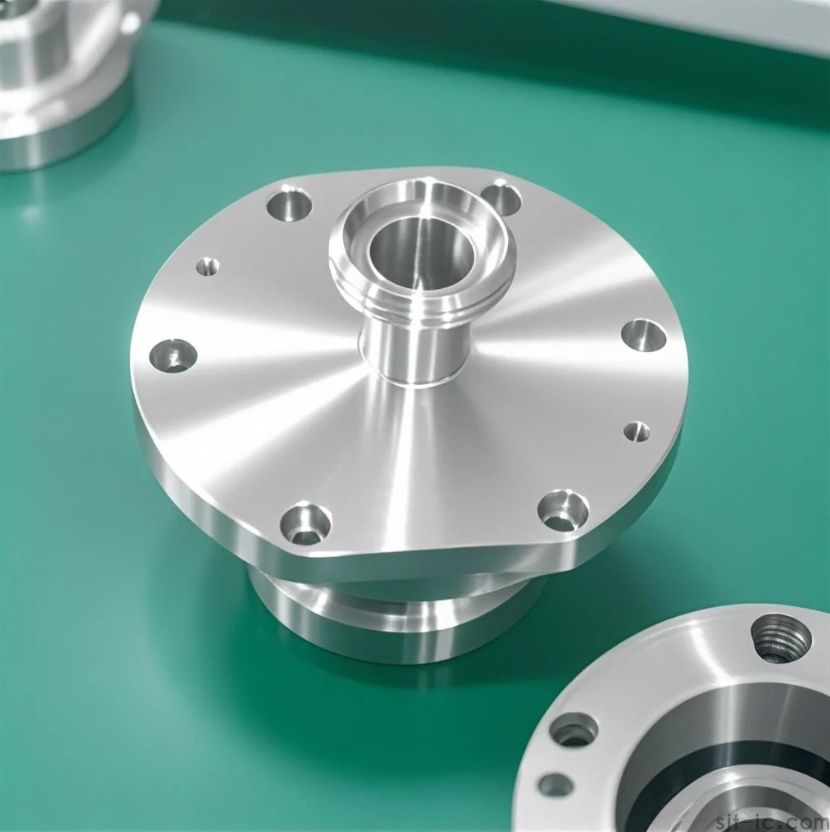

The medical industry demands exceptional precision and biocompatible materials. Our CNC machining services for medical applications include surgical instruments, implant components, diagnostic equipment parts, and prosthetics, all manufactured with ISO 13485 compliance.

Key Capabilities of Top Medical CNC Manufacturers

1. Micro-machining for intricate surgical tools (tolerances to ±.005mm)

2. Multi-axis machining for complex geometries

3. Biocompatible material expertise (Ti-6Al-4V, PEEK, surgical stainless steels)

4. Complete surface finishing and sterilization-ready processing

EMAR's Advantage in Medical CNC Machining

Our medical-grade CNC production features:

- Class 10,000 cleanroom machining options

- Full material traceability documentation

- FDA-compliant validation protocols

- Risk management per ISO 14971

Material Selection for Medical Applications

We machine all FDA-approved materials including:

• 316LVM stainless steel

• Cobalt-chrome alloys

• Titanium grades (CP Ti, Ti-6Al-4V ELI)

• Medical-grade plastics (PEEK, UHMWPE, PTFE)

Quality Assurance Protocols

Every medical component undergoes:

- 3D scanning and CMM inspection

- Surface roughness verification

- Sterilization validation testing

- Lot-controlled documentation

For mission-critical medical components that can't compromise on precision or biocompatibility, trust EMAR's certified CNC machining solutions. Contact our medical device specialists today to discuss your project requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque