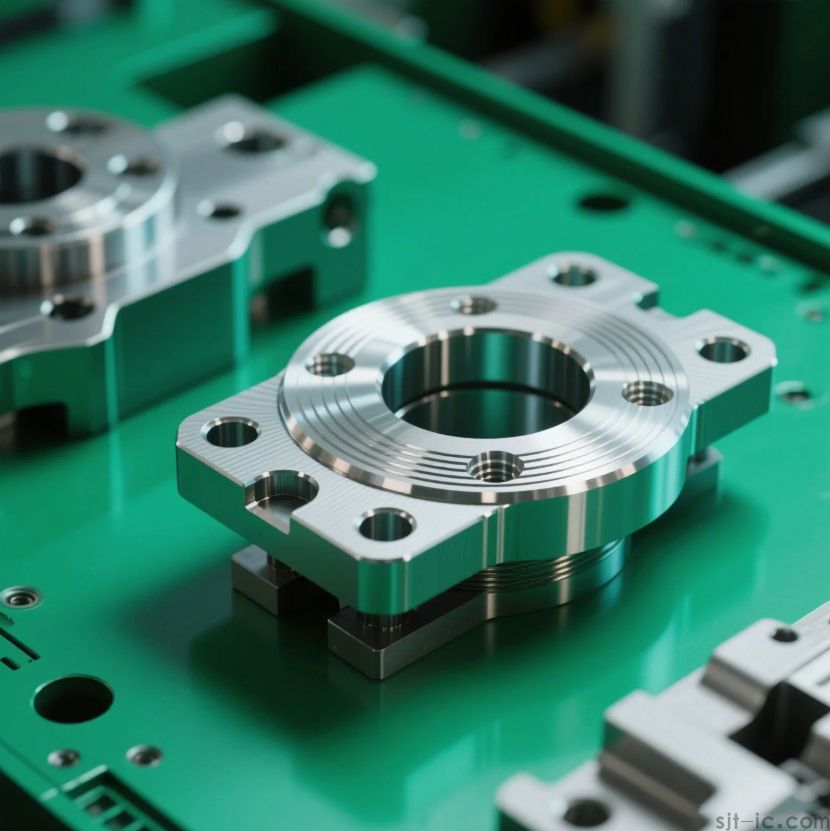

In today's competitive manufacturing landscape, CNC non-standard precision machining customization has become a critical solution for industries requiring unique, high-accuracy components. As a leading provider at EMAR, we specialize in delivering tailored machining services that meet the most demanding specifications.

Understanding CNC Non-Standard Precision Machining

Unlike standard machining processes, non-standard precision machining involves creating components with unique geometries, tight tolerances (often within ±.005mm), and specialized material requirements. Our 5-axis CNC machines and advanced metrology equipment ensure we can handle even the most complex custom projects.

Our Customization Process

EMAR's approach to CNC Machining customization follows a rigorous 6-step workflow:

Requirement Analysis: Our engineers review your technical drawings and specifications

Material Selection: Recommending optimal materials from aerospace aluminum to medical-grade plastics

Process Planning: Developing customized toolpaths and machining strategies

Prototype Development: Creating test pieces for validation

Quality Assurance: Conducting CMM inspections and surface roughness tests

Final Delivery: Packaging with anti-corrosion treatment when required

Industries We Serve

Our non-standard machining solutions support:

Aerospace: Lightweight structural components with complex contours

Medical: Biocompatible implants with micron-level precision

Automotive: Custom jigs and fixtures for EV battery production

Electronics: Heat sinks with optimized thermal performance

Why Choose EMAR for Your Custom Projects

With 15+ years in precision machining, we offer:

ISO 9001:2015 certified quality management

50+ CNC machines with Swiss-type lathes and vertical machining centers

In-house surface treatment capabilities (anodizing, plating, painting)

Strict confidentiality agreements for proprietary designs

Competitive MOQs from prototype to mass production

Contact our engineering team today at www.sjt-ic.com to discuss your custom machining requirements. We provide DFM analysis free of charge for all potential projects.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque