When searching for a reliable stainless steel CNC Machining manufacturer, quality, precision, and service are non-negotiable factors. As a professional CNC machining service provider, EMAR Technologies specializes in delivering high-performance stainless steel components for industries ranging from aerospace to medical equipment. This guide will help you identify the key criteria for selecting the right manufacturer.

Why Choose Stainless Steel CNC Machining?

Stainless steel is favored for its corrosion resistance, durability, and mechanical properties. CNC machining ensures tight tolerances (up to ±.005mm) and complex geometries, making it ideal for critical applications like surgical instruments or automotive parts.

Key Selection Criteria for Manufacturers

1. Certifications & Standards: ISO 9001 and AS910 compliance (like EMAR's facility) guarantee consistent quality.

2. Material Expertise: Look for experience with 304/316L, 17-4PH, and other grades.

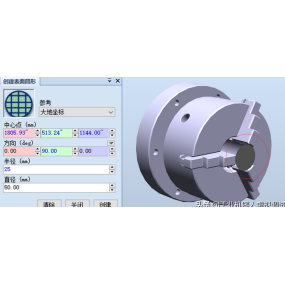

3. Advanced Equipment: 5-axis CNC mills and Swiss-type lathes enable complex designs.

4. Post-Processing Capabilities: Passivation, electropolishing, or bead blasting services.

EMAR's Competitive Edge

With 15+ years in precision CNC machining, EMAR offers:

• Prototype-to-mass production with 98% on-time delivery

• In-house quality lab (CMM, optical comparators)

• DFM feedback to optimize your designs

• Competitive pricing for medical/OEM sectors

Common Industry Pain Points Solved

• Surface finish issues: Our mirror polishing achieves Ra .2μm.

• Thread galling: Proprietary toolpath programming prevents material adhesion.

• Lead time pressure: 72-hour rapid turnaround for urgent projects.

For your next stainless steel project, request a free quote at EMAR's official website or contact our engineering team for technical consultations.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque