You've got a brilliant design in your hands. A custom part that's crucial for your new product prototype or that machine upgrade. It's not something you can buy off the shelf – it needs CNC non-standard machining. But here's the headache: a quick online search throws up dozens, maybe hundreds, of factories claiming they can do it. How on earth do you pick the right one? 🤔 Choosing wrong can mean delayed projects, wasted budget, and parts that just don't fit. Let's cut through the noise. This isn't about finding a factory; it's about finding a reliable partner for your custom machining needs.

What Exactly Are You Looking For in a "Reliable" Factory?

First things first, let's define "reliable." In the world of custom parts, reliable means more than just delivering on time. It means clear communication from the get-go. It means they ask smart questions about your design files. It means they can handle the complexities of your part without overpromising. A reliable factory makes you feel like your project is in safe hands, not just another order number. Think of it this way: you're not just buying a service; you're buying peace of mind and a guarantee that your vision becomes a precise, physical reality.

Key Checkpoints Before You Even Make Contact

Don't just jump at the first quote! Do some detective work first. Here's what I always check:

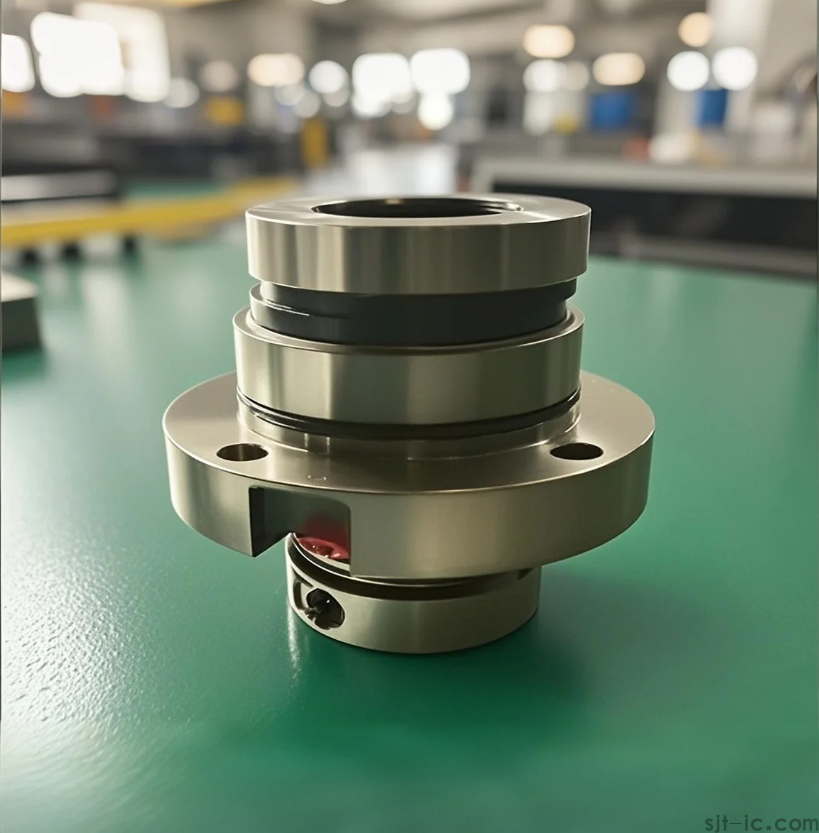

1. Their Online Portfolio & Case Studies: Do they show examples similar to what you need? Look for complexity, materials used (like aluminum, stainless steel), and surface finishes. A blank or generic gallery is a red flag. 🚩

2. Equipment List: Can they handle your job? A factory with only 3-axis machines might struggle with complex 5-axis parts. Look for mentions of multi-axis CNC mills, lathes, and maybe even EDM or wire cutting for specialized needs.

3. "About Us" & Certifications: How long have they been around? Do they mention quality control processes (like ISO 9001)? While not a perfect guarantee, it shows a mindset towards system and standards.

My personal rule? If their website looks like it's from 2005 and provides zero useful technical information, I'm already skeptical. In this business, a professional online presence often, but not always, correlates with a professional workshop. However, the real test comes next.

The Make-or-Break: Communication & The Quoting Process

This is where you separate the pros from the ** s. Send your drawings (STEP or IGES files are best) and ask for a quote. Pay close attention to how they respond.

✅ The Green Flags:

- They reply with specific questions about tolerances, material grade, or surface finish requirements you might have omitted.

- They suggest potential design optimizations for easier machining or lower cost – this shows experience and a desire to help.

- The quote is detailed, breaking down costs for material, machining, and any post-processing.

❌ The Red Flags:

- They give you a price immediately without any questions. This perhaps suggests they didn't really look at the details.

- Communication is slow, vague, or full of technical jargon they can't explain simply.

- The quote is a single, round number with no breakdown. Transparency matters.

I've learned that a good engineering conversation during quoting is worth more than a slightly cheaper price from a silent vendor. It sets the tone for the entire project.

Don't Skip This Step: Asking for a Sample or Pilot Run

For a larger order or a critical part, this is non-negotiable. Propose a small pilot run first. Yes, the unit cost will be higher, but it's your insurance policy.

What are you testing?

- Quality: Do the parts match the drawings? Check dimensions, finish, and overall feel.

- Communication Loop: How do they handle feedback if the first sample isn't perfect?

- Logistics: Is packaging secure? Are documents (inspection reports) clear?

This step turns abstract promises into tangible proof. A factory confident in its abilities will welcome this approach. If they push back hard on a pilot run for a custom job, that's a sign to walk away. But, having said that, for very simple, low-cost parts, you might judge the risk acceptable to go straight to a small batch.

Putting It All Together & Making Your Decision

So, you've shortlisted 2-3 factories. They all seem technically capable. How to choose? Look beyond the machine. Consider the team you'll be working with. Was there a project engineer you connected with? Did they seem genuinely interested in solving your problem?

Sometimes, the "perfect" factory on paper feels rigid and transactional, while another with slightly older equipment has a fantastically responsive and proactive team. For non-standard work, where issues can pop up, that human factor – the willingness to go the extra mile – is priceless. Trust your gut feeling from all the interactions you've had.

Finding the right CNC Machining partner is a mix of hard facts and soft skills. It takes a bit of legwork upfront, but the payoff is a smooth project, a part you're proud of, and a go-to supplier you can rely on for future work. If you're in the middle of this selection process and want a second opinion on a quote or a factory's capabilities, why not discuss your specific part with a specialist? 👉 [Get a professional evaluation for your custom part project].

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque