So, you've got a design. It's not something you can pull off a shelf. It's unique, it's complex, and it's crucial for your project. You need someone to make it real, and not just anyone—you need a CNC non-standard machining manufacturer. But with so many shops out there, how do you pick the right partner and not just another vendor? It feels like a gamble, right? One wrong choice could mean delayed timelines, blown budgets, or parts that just don't work. Let's cut through the noise and talk about what really matters when making this decision. 🤔

What Exactly Are You Looking For?

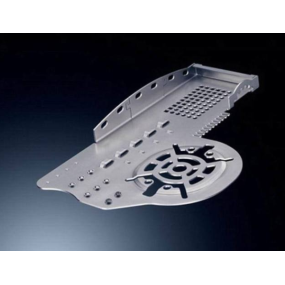

First things first, let's get clear on the "non-standard" part. We're not talking about mass-producing the same bolt a million times. We're talking about custom, one-off, or low-volume parts that require special attention. The manufacturer you choose needs to thrive on this kind of challenge, not just tolerate it. They should see your complex blueprint as a puzzle they're excited to solve, not a headache. If their website only shows rows of identical parts, that's your first red flag. 🚩

The Big Three: Capability, Communication, and Proof

Okay, let's break down the core things you should be digging into. Think of it as a three-legged stool—if one leg is weak, the whole thing topples.

1. Technical Capability & Equipment: This is the obvious one, but look beyond the list of machines. Ask about their experience with your specific material (is it aluminum, titanium, or a tricky plastic?). Can they handle the tolerances your design demands? A shop with a shiny new 5-axis machine is great, but if their operators don't have the expertise for tight-tolerance work, it's just an expensive paperweight. I always say, “The machine tells you what they can do; the operator tells you how well they can do it.”

2. Communication & Process: Here's where many projects go off the rails. You need a point of contact who understands both engineering and your business needs. How do they handle design feedback? A good manufacturer will point out potential manufacturing issues before the tool hits the metal, saving you time and money. Do they provide regular updates? The silence between order and delivery can be deafening if you're not working with a communicative partner.

3. Evidence of Quality & Reliability: Anyone can say they do "high-quality" work. You need proof. Ask for:

• Case studies or photos of past complex projects.

• Their quality control process (Do they just check the last part, or do they have in-process checks?).

• References or testimonials, if possible.

Seeing is believing. A manufacturer proud of their work will have this evidence ready.

Don't Let Price Be Your Only Guide

We all have budgets. I get it. But choosing a CNC Machining partner solely on the lowest quote is often the most expensive mistake you can make. A suspiciously low price might hint at corners being cut—maybe on material quality, operator skill, or that crucial quality control step. A higher quote might include valuable services like design for manufacturability (DFM) analysis, better packaging, or more rigorous testing. Think total cost, not just unit price. A part that fails in the field costs infinitely more than one done right the first time. However, having said that, the most expensive option isn't automatically the best either. The goal is to find the point where fair price meets demonstrated value.

The "Feel" of the Partnership

This is the intangible, but it's huge. When you talk to them, do they ask smart questions about your project's application and end-use? Or are they just waiting for you to send the file so they can give a price? A partner is invested in your success; a vendor is just processing an order. I've found that the best manufacturers have a kind of curious, problem-solving mindset. They might even suggest alternative approaches you hadn't considered. That collaborative "feel" is a strong indicator you're on the right track.

Ready to Start a Conversation?

Choosing the right manufacturer is part research, part instinct. You're not just buying a service; you're forming a technical partnership to bring your idea to life. It's worth taking the time to get it right.

If you have a specific non-standard project in mind and want to discuss how it could be manufactured with a team that values clear communication and proven results, the next step is to start a dialogue. 👉 Reach out to our technical team today with your drawings or ideas. Let's see if we can build something great together.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque