Why Choose Aluminum Alloy for Custom Non-Standard Machining?

Aluminum alloy stands out as the preferred material for custom non-standard parts, and EMAR’s rigorous material selection process ensures we harness its full potential:

- Exceptional Strength-to-Weight Ratio: Aluminum’s density is approximately one-third that of steel, enabling lightweight components without compromising mechanical strength—critical for aerospace, automotive, and robotics applications where weight reduction drives performance and efficiency.

- Superior Machinability: Aluminum is easier to cut, drill, mill, and form than steel, brass, or titanium, reducing machining time, energy consumption, and tool wear. This translates to faster lead times and cost-effective production for complex non-standard designs.

- Outstanding Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air, and specialized alloys (e.g., 5052, 6061) offer enhanced resistance to chemicals, saltwater, and harsh environments—eliminating the need for excessive post-processing in many cases.

- Versatile Functional Properties: Aluminum exhibits excellent thermal and electrical conductivity, non-magnetic characteristics, and low-temperature resistance, making it ideal for electronic components, heat sinks, medical devices, and industrial equipment.

- Sustainability & Cost-Effectiveness: Aluminum is 100% recyclable with minimal loss of quality, aligning with eco-friendly manufacturing goals. Its machinability and availability also reduce material waste and production costs compared to other metals.

Premium Aluminum Alloys for Precision Non-Standard Machining

EMAR offers a comprehensive range of aluminum alloys, each selected for its unique properties to match your project’s specific demands. Our engineering team provides expert guidance to help you choose the optimal alloy for performance, cost, and manufacturability:

| Alloy Grade | Key Properties | Advantages | Typical Applications |

|---|---|---|---|

| 6061-T6 | Heat-treatable, excellent machinability/weldability, good corrosion resistance | Versatile, cost-effective, balanced strength and ductility | Electrical fittings, bike frames, auto parts, industrial tools, structural components |

| 6063-T6 | Superior formability, smooth anodizing performance, moderate strength | Ideal for extrusions, decorative parts, and architectural components | Door/window frames, railings, pipes, consumer product enclosures |

| 7075-T6 | Ultra-high strength (one of the strongest commercial alloys), fatigue resistance | Exceptional load-bearing capacity for high-stress applications | Aerospace structures, aircraft fittings, mold tools, high-performance gears |

| 5052-H32 | Non-heat-treatable, outstanding corrosion resistance, excellent weldability | Saltwater-resistant, easy to form—perfect for marine and outdoor use | Fuel tanks, sheet metal parts, marine components, electrical enclosures |

| 2024-T3 | High tensile strength, fatigue resistance, good machinability | Ideal for high-strength, low-weight structural parts | Aircraft bolts, pistons, aerospace fittings, heavy-duty machinery components |

| 5083 | Al-Mg alloy, excellent weldability, cold workability, corrosion resistance | Medium strength, suitable for harsh environments | Ship hulls, oil pipelines, automotive chassis parts, offshore equipment |

| 7050-T7651 | High strength, stress corrosion resistance, heat-treatable | Superior to 7075 for critical aerospace applications | Aircraft bulkheads, fuselage frames, high-pressure components |

| MIC-6 (Jig Plate) | Stress-relieved, zero internal stresses, high dimensional stability | Precision machining without distortion | Assembly jigs, fixture plates, test structures, high-accuracy tooling |

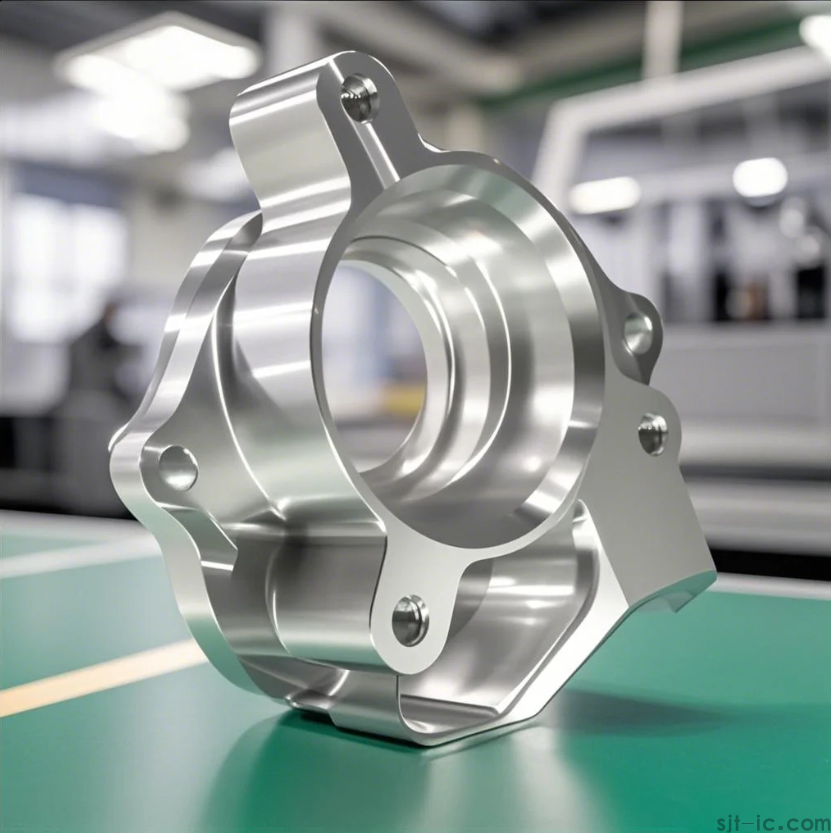

Advanced Machining Processes & Capabilities

EMAR’s investment in cutting-edge CNC technology and machining processes ensures we deliver non-standard aluminum parts with unmatched precision and consistency:

- CNC Milling & Turning: Equipped with 3-axis, 4-axis, and 5-axis CNC Machining centers (including pentahedron models), we handle complex geometries, undercuts, and tight tolerances—down to ±0.005mm for critical applications.

- 5-Axis Linkage Machining: Enables one-step processing of multi-sided, intricate parts (e.g., aerospace components, robotic actuators), reducing setup time and improving dimensional accuracy.

- EDM (Electrical Discharge Machining): Ideal for hard-to-reach features, micro-details, and non-conventional shapes that traditional machining cannot achieve.

- Precision Grinding & Finishing: Ensures surface smoothness and dimensional uniformity for high-precision parts like medical device components and electronic connectors.

- Custom Non-Standard Solutions: No matter the complexity—from cavity parts and gears to housings and prototypes—we support low-volume (1 piece) to high-volume (100,000+ pieces) production with flexible manufacturing workflows.

Our machining process adheres to strict quality control at every step:

- Design Feasibility Review: Our engineers analyze your 2D/3D CAD files (Solidworks, Pro/E, AutoCAD, PDF) to optimize for manufacturability, reduce costs, and ensure compliance with your requirements.

- CAM Programming: Advanced CAM software generates precise tool paths, minimizing material waste and maximizing efficiency.

- Precision Machining: Automated CNC machines execute operations with consistent accuracy, monitored by skilled technicians.

- In-Process Inspection: Real-time quality checks using coordinate measuring machines (CMM), hardness testers, and optical instruments ensure adherence to tolerances.

Comprehensive Surface Finishing Solutions

EMAR offers over 30 surface treatment options to enhance the performance, durability, and aesthetics of your custom non-standard aluminum parts. Our finishing processes are tailored to your application’s needs—whether you require corrosion resistance, wear protection, or decorative appeal:

- Anodizing (Type II, III): Forms a hard, uniform oxide layer that improves corrosion/wear resistance and allows for custom colors (clear, black, red, blue, etc.). Ideal for consumer products, automotive parts, and outdoor equipment.

- Powder Coating: Electrostatically applied and cured at high temperatures, providing a durable, scratch-resistant finish in a wide range of colors. Suitable for industrial enclosures, architectural components, and automotive accessories.

- Plating: Nickel, chrome, zinc, or silver plating enhances conductivity, lubricity, or decorative appeal. Used in electronic connectors, fasteners, and medical devices.

- Mechanical Finishes: Sandblasting (for matte texture), brushing (for linear aesthetics), and polishing (for mirror-like surfaces) improve visual appeal and prepare parts for further treatment.

- Chemical Treatments: Passivation (enhances corrosion resistance), Alodine (chromate conversion coating), and chemical polishing ensure long-term performance in harsh environments.

- Laser Engraving & Marking: Adds logos, part numbers, or serial codes for traceability and branding.

Industry-Specific Applications

EMAR’s aluminum alloy custom non-standard parts machining serves a wide range of industries, with tailored solutions that meet sector-specific standards and requirements:

- Aerospace & Defense: AS9100D certified, we produce lightweight, high-strength components (e.g., aircraft fittings, engine parts) using alloys like 7075 and 2024, adhering to strict ITAR regulations.

- Automotive: Precision parts for electric vehicles (EVs), traditional automobiles, and motorcycles—including engine components, chassis parts, and interior accessories—with tolerances as tight as ±0.01mm.

- Medical Devices: ISO 13485 certified, we manufacture biocompatible, sterile parts (e.g., surgical instruments, device housings) using corrosion-resistant alloys and environmentally friendly materials.

- Robotics & Automation: High-precision gears, housings, and actuators that withstand repeated motion, leveraging 5-axis machining for complex geometries.

- Electronics & Consumer Products: Heat sinks, enclosures, and connectors that benefit from aluminum’s thermal conductivity and lightweight properties.

- Industrial Equipment: Durable components for machinery, tooling, and infrastructure—including valves, brackets, and sensor housings—designed for heavy-duty use.

- Marine & Offshore: Corrosion-resistant parts (e.g., fuel tanks, pipe fittings) using alloys like 5052 and 5083, built to withstand saltwater environments.

EMAR’s Competitive Advantages

What sets EMAR apart as a leader in aluminum alloy custom non-standard parts machining?

- Decades of Expertise: 25+ years of experience in CNC machining, with a team of 200+ certified engineers and technicians specializing in aluminum alloy processing.

- State-of-the-Art Equipment: 35+ CNC machines (including 5-axis, turning-milling compound, and ultra-precision models) ensure we handle the most complex non-standard designs with ease.

- One-Stop Service: From design consultation and prototyping to machining, finishing, and delivery—we eliminate intermediate steps, saving you time and reducing communication costs.

- Rapid Response & Delivery: 2-hour quotation for most projects, 3-day expedited prototyping, and 7-day standard production lead times. We also provide weekly progress reports (photos/videos) for full transparency.

- Strict Quality Certifications: ISO 9001:2015, ISO 13485, and AS9100D certified, with a 98%+ pass rate and 100% final inspection for every order.

- High Customer Retention: 85%+ repeat customer rate across industries, a testament to our reliability, quality, and customer service.

- Flexible Collaboration: We accept customer-supplied materials (with grade/state verification) and support custom packaging (PE bags, cartons, wooden cases) and logistics (DHL, TNT, sea/air freight).

Quality Assurance & Compliance

EMAR’s quality management system is built to meet global standards, ensuring your custom non-standard parts are consistent, reliable, and compliant:

- Material Traceability: All aluminum alloys are sourced from certified suppliers with complete material certificates (Mill Test Reports).

- Multi-Stage Inspection: IQC (Incoming Quality Control) for raw materials, PQC (Process Quality Control) during machining, and FQC (Final Quality Control) before delivery.

- Advanced Testing Equipment: CMM for dimensional accuracy, hardness testers, corrosion tests, and surface roughness meters.

- Environmental Compliance: RoHS and REACH certified, using eco-friendly materials and processes to minimize environmental impact.

Frequently Asked Questions (FAQ)

1. What file formats do you accept for custom non-standard parts?

We accept 2D/3D CAD files in Solidworks, Pro/E, AutoCAD, PDF, STEP, and IGES formats. Please include material specifications, tolerances, surface treatment requirements, and quantity for a accurate quote.

2. Can EMAR process customer-supplied aluminum materials?

Yes. We require confirmation that your aluminum grade and state are suitable for machining and post-processing. Our team will verify material compatibility before production.

3. What is the minimum order quantity (MOQ) for non-standard parts?

We have no strict MOQ—we support prototype orders (1 piece) to mass production (100,000+ pieces). Trial orders are welcome before full-scale production.

4. How long does it take to receive a quote and deliver the parts?

- Quote: Within 2 hours for most projects (24 hours for highly complex designs).

- Delivery: 3 days for expedited prototyping, 7 days for standard production, and 10-15 days for high-volume orders. Lead times may vary based on complexity and quantity.

5. Which aluminum alloy is best for anodizing?

High-purity aluminum and 5xxx/6xxx series alloys (e.g., 5052, 6061, 6063) are ideal for anodizing, as they produce smooth, uniform oxide layers with excellent corrosion resistance and color retention.

6. How does EMAR ensure the precision of complex non-standard parts?

We combine 5-axis machining technology, advanced CAM programming, in-process inspection, and skilled engineering to achieve tight tolerances (±0.005mm). Our stress-relieved alloys (e.g., MIC-6) minimize deformation during machining.

Partner with EMAR for Your Aluminum Alloy Custom Non-Standard Machining Needs

At EMAR, we are committed to turning your custom non-standard aluminum part designs into reality—with precision, efficiency, and reliability. Whether you need a single prototype or a large production run, our team of experts will work closely with you to deliver solutions that exceed your expectations.Get Started Today: Send your 2D/3D CAD files, material requirements, and project details to sales8@sjt-ic.com for a free, no-obligation quote within 2 hours. Our engineering team is available 24/7 to answer your questions and provide design support.EMAR—Your Trusted Partner for High-Precision Aluminum Alloy Custom Non-Standard Parts Machining.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque