Ever had a brilliant product idea, a crucial machine part that broke, or a design tweak that could revolutionize your assembly line... only to hit a wall when you need just 10, 50, or 100 pieces made? 😫 You're not alone. For engineers, procurement managers, and startup founders, finding a reliable partner for small batch CNC Machining and prototyping can feel like searching for a needle in a haystack. The big factories often have sky-high minimum order quantities (MOQs), while the question of quality, precision, and true customization looms large. So, how do you navigate this? Let's break it down, step by step.

What Exactly is Small Batch CNC Prototyping?

Think of it as a test drive for your design before you commit to mass production. It's the process of using Computer Numerical Control (CNC) machines to produce a limited number of physical parts—anywhere from a single piece to a few hundred—based on your exact digital blueprint (like a CAD file). The goal isn't just to get parts; it's to validate form, fit, and function, test materials, and iron out any kinks in the design with minimal financial risk. It's the bridge between a great idea on your screen and a great product in your hand.

Why Go for Small Batches Instead of a Full Production Run?

This might seem obvious, but the reasons go deeper than just "we don't need many."

1. Risk Mitigation: Imagine committing to 10,000 units only to find a design flaw in the 100th piece. Small batches let you fail fast and cheap, which is actually a smart strategy. It's like checking the water with your toes before diving in.

2. Cost-Effectiveness for Development: Upfront tooling costs for methods like injection molding are huge. CNC machining for small batches often requires no custom tooling, keeping your initial investment low. You pay mostly for machine time and material.

3. Unmatched Flexibility: Got feedback from testing? Need to change a diameter by .5mm? With small batch CNC, you can revise your CAD file and have a new version in days, not months. This agility is gold for innovation.

However, and this is a big "however," the cost per piece in small batches is higher than in mass production. You're not benefiting from economies of scale. So the real question becomes: is the value of learning and flexibility worth that higher unit cost for now? For most development cycles, the answer is a resounding yes.

The Real-World Process: From Your Mind to a Part in Hand

How does it actually work? Let's walk through it like you're explaining it to a colleague.

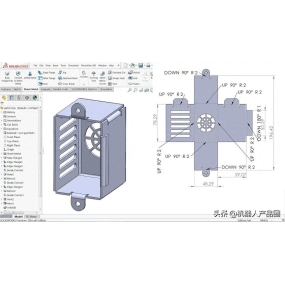

Step 1: The Digital Handshake (Your Design Files). It all starts with you. You provide a 3D CAD model (like .STEP or .IGES files) and possibly 2D drawings. Clear, complete files are the number one thing that speeds everything up. I often tell people, "The time you spend perfecting your CAD file is time and money saved later."

Step 2: The Technical Chat (DFM Feedback). A good partner won't just take your file and run. They'll provide Design for Manufacturability (DFM) feedback. This might sound technical, but it's simply their engineer saying, "Hey, this internal corner is too sharp for our tool to reach, can we add a small radius? It'll make the part stronger and cheaper to machine." This step is crucial—it's where expertise saves you from costly mistakes.

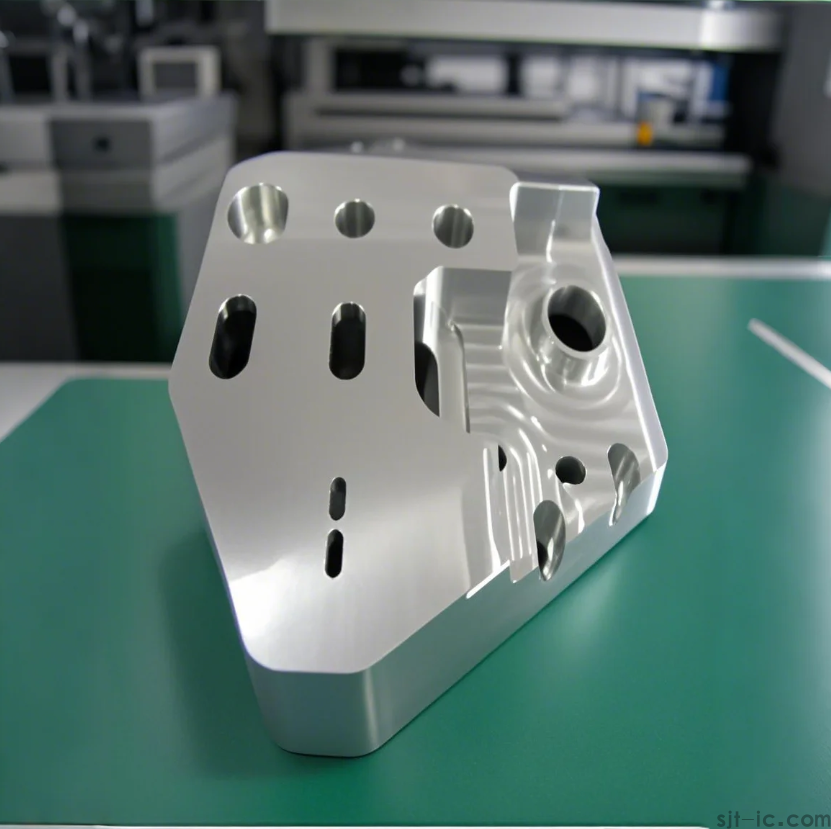

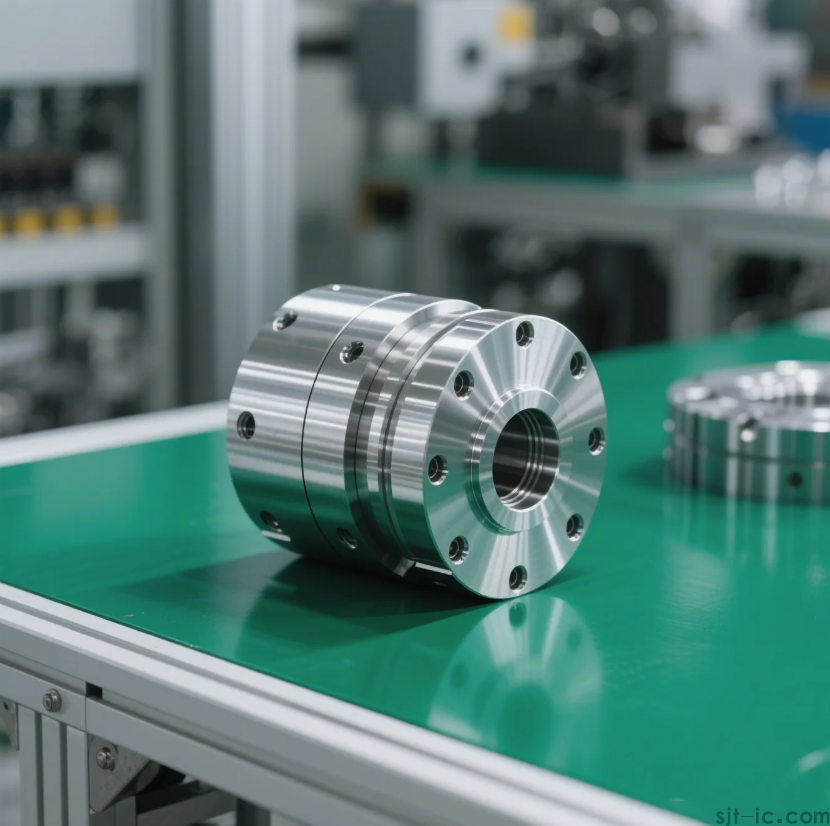

Step 3: The Behind-the-Scenes Magic (Programming & Setup). Their programmer creates toolpaths for the CNC machines. For small batches, efficient programming is key to keeping costs down. Then, the machine is set up with the right material (aluminum, stainless steel, plastic, etc.) and tools.

Step 4: Machining & Quality Checks. The machines run, often unsupervised. But here's the personal insight: the real value isn't in the machine running; it's in the in-process and post-process inspections. Using calipers, micrometers, and maybe even a CMM (Coordinate Measuring Machine) for critical features, they check dimensions against your drawing. This is non-negotiable for reliable prototyping.

Step 5: Finishing & Delivery. Need a smooth finish? Anodizing? Painting? This is done now. Then, your precious few parts are carefully packaged and shipped directly to you.

How to Spot a Partner Who Gets It (And Avoids Who Doesn't)

Not all machine shops are created equal for this kind of work. Here’s what to look for:

✅ They Ask a Lot of Questions: About the part's function, the assembly it goes into, the stresses it will face. This shows they're thinking with you, not just working for you.

✅ They're Transparent About Communication: Can you get quick updates? Will they send you photos of issues? For small batches, you're not just a PO number; you should feel like a project.

✅ They Have the Right Toolbox: A mix of modern 3-axis, 5-axis CNC mills, and lathes. Versatility means they can choose the most efficient way to make your part.

❌ The Red Flag: A quote that comes back suspiciously fast with no questions asked. That might indicate they didn't really look at your design, which can lead to surprises (the bad kind) later.

Making the Leap: Your Next Step

So, you've got the knowledge. You understand that small batch CNC prototyping is less about cheap parts and more about cost-effective validation and speed-to-market. It's a strategic step. The barrier now is just taking action.

If you're sitting on a CAD file for a part that could solve a problem, improve a product, or kickstart a project, the hardest part is done. The next move is to have a conversation with a specialist who speaks this language. They can turn those digital geometries into tangible reality, one precise, small batch at a time.

Ready to see if your design holds up in the real world? A professional consultation can map out the entire journey, from file review to final delivery, giving you clarity and confidence. Sometimes, all it takes is that first conversation to move from "what if" to "what's next."

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque