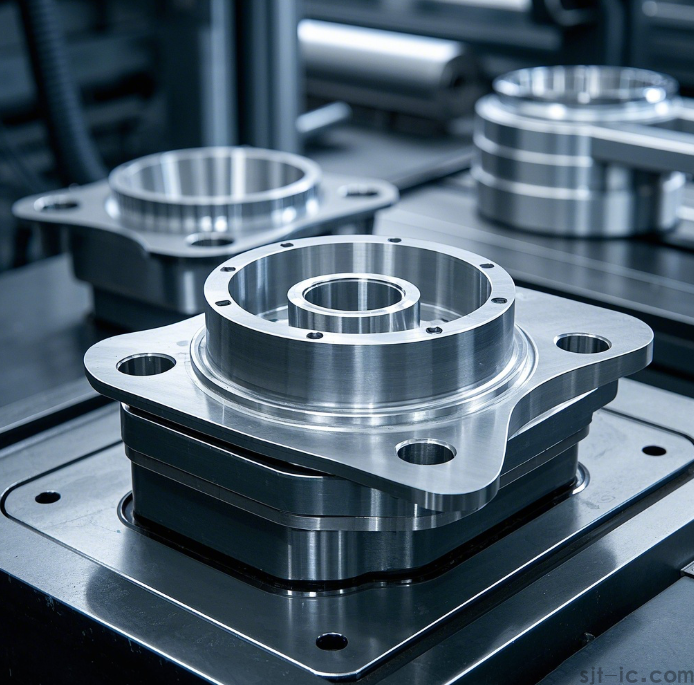

As a leading CNC Machining service provider, EMAR specializes in delivering high-precision components for industries ranging from aerospace to medical devices. Our expertise in CNC precision product machining process ensures exceptional quality, tight tolerances, and repeatability for every project.

Understanding CNC Precision Machining

Precision CNC machining involves subtractive manufacturing techniques where computer-controlled machines remove material from a workpiece to create complex geometries with micron-level accuracy. At EMAR, we utilize advanced 5-axis CNC machines, Swiss-type lathes, and milling centers to achieve surface finishes as fine as Ra .2μm.

Key Stages in Our CNC Precision Process

1. Design Analysis: Our engineers review CAD models for manufacturability

2. Material Selection: Aerospace-grade aluminum, titanium, or engineering plastics

3. Machine Programming: Optimized toolpaths for efficiency and precision

4. Quality Assurance: In-process inspections using CMM and optical comparators

Why Choose EMAR for Precision Machining?

With ISO 9001:2015 certification and CNC machining capabilities that include micro-machining down to .01mm tolerances, we guarantee:

- 99.8% on-time delivery rate

- Material traceability for critical applications

- Full DFM support and prototyping services

Visit EMAR's official website to request a free project evaluation and discover how our CNC precision product machining process can optimize your manufacturing outcomes.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque