As a professional CNC Machining service provider, EMAR specializes in manufacturing precision components like pulleys with advanced CNC technology. This article will explain the complete process of CNC pulley machining, addressing common concerns of procurement managers and engineers.

Understanding CNC Pulley Machining

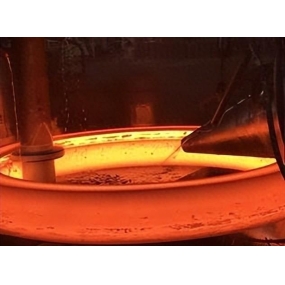

Pulleys are critical power transmission components requiring high dimensional accuracy. CNC machining ensures precise groove profiles, bore diameters, and surface finishes through automated, computer-controlled processes.

Key Steps in CNC Pulley Manufacturing

1. Material Selection: Typically aluminum, steel, or engineered plastics based on application requirements

2. CNC Turning: Creates the basic cylindrical form and bore

3. Groove Cutting: CNC milling machines precisely cut V-grooves or timing belt profiles

4. Finishing: Includes deburring, anodizing (for aluminum), or heat treatment

Why Choose EMAR for Your Pulley Machining

Our advantages include:

15+ years of CNC machining experience

±.01mm dimensional tolerance capability

ISO 9001 certified quality management

One-stop service from design to delivery

For reliable CNC pulley machining solutions, visit our official website at https://www.sjt-ic.com/ to request a quote or technical consultation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque