Understanding CNC Machining Parts Cost Factors

When evaluating CNC machining parts cost, several critical factors come into play. As a professional CNC machining service provider, EMAR Company helps clients understand these variables to make informed decisions about their manufacturing projects.

Key Elements Affecting CNC Machining Pricing

The primary components influencing CNC machining parts cost include:

Material Selection: Aluminum, steel, titanium, and plastics each have different price points

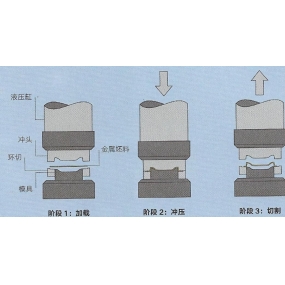

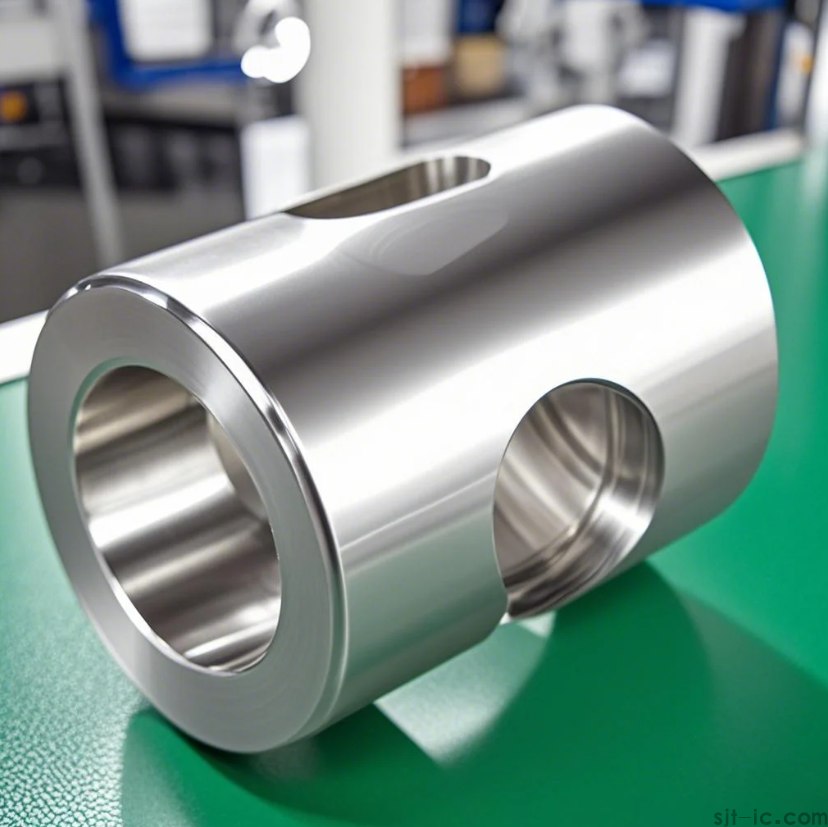

Part Complexity: Intricate designs require more machining time and specialized tooling

Quantity: Higher volumes typically reduce per-unit costs through economies of scale

Tolerances: Tighter tolerances demand more precise machining and inspection

Surface Finishing: Additional treatments like anodizing or polishing add to the cost

How EMAR Optimizes Your CNC Machining Costs

At EMAR Company, we employ several strategies to help clients manage their CNC machining parts cost effectively:

Design for Manufacturability (DFM) analysis to suggest cost-saving modifications

Advanced CNC equipment that maximizes efficiency and minimizes waste

Bulk material purchasing that reduces raw material expenses

Precision tooling management to extend tool life and reduce replacement costs

Getting an Accurate CNC Machining Quote

For the most precise cost estimation, we recommend submitting your CAD files to our engineering team. Our experts will analyze your requirements and provide a detailed breakdown of all cost components, ensuring transparency in pricing and helping you make the best decision for your project budget.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque