Ever had a brilliant product idea, a prototype that needs to be perfect, or a machine that's down because a single, weird-shaped part broke? You need maybe 50 pieces, not 500. You Google "machining shop," and most of them give you that look—the "talk to us when you need a truckload" vibe. 😓 So, where do you go for small batch CNC custom machining that actually cares about your project, not just your order size? That's the real question we're tackling today.

What Exactly Are Small Batch CNC Custom Machining Services?

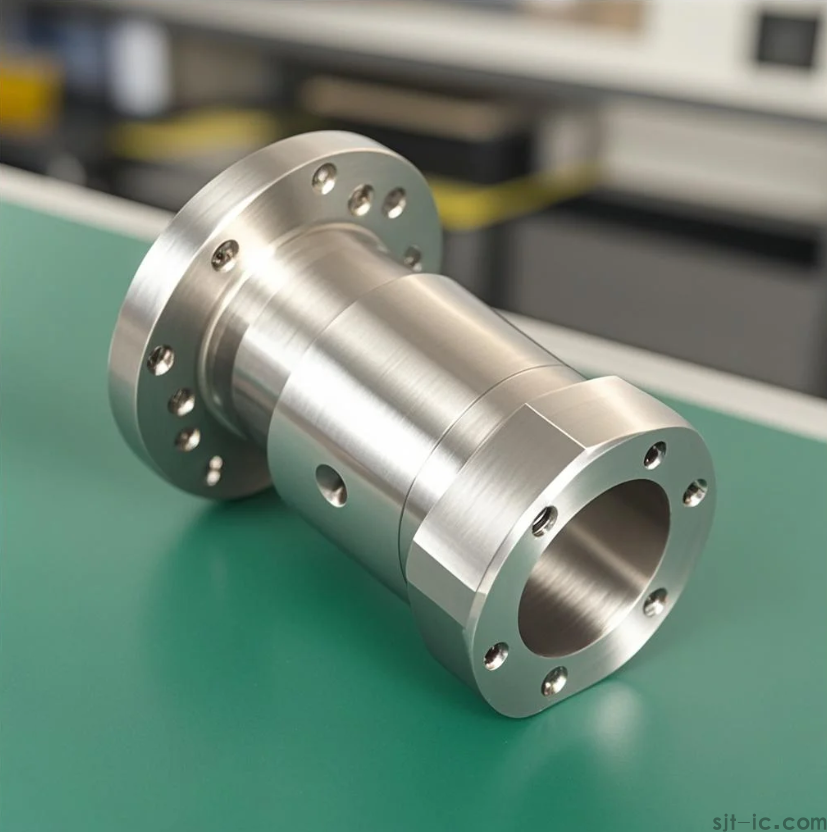

Let's cut through the jargon. Imagine you need custom metal or plastic parts, designed by you, made with high precision. You only need a small number of them—anywhere from 1 piece to a few hundred. Small batch CNC custom machining services are workshops or companies that specialize in exactly that. They're the partners for R&D departments, startup founders, and maintenance engineers who need quality, flexibility, and attention to detail over massive volume discounts. It's not about running a machine non-stop for weeks; it's about getting your unique part made right, efficiently.

Why Is Finding a Good Small-Batch Service So Tricky?

You'd think it's easy, but here's the catch. Many large machine shops are built for efficiency in repetition. Setting up a CNC machine for a run of 10 pieces often takes almost as much time and skill as for 100 pieces. For them, small batches mean high cost per part and "inefficient" use of their time. However, this is where specialized small-batch services shine. They've optimized their workflow, quoting, and communication for exactly this scenario. The challenge for you is filtering out the volume-focused shops to find these agile partners.

How Does The Process Usually Work? A Step-by-Step Look

Knowing the process helps you be a better customer and spot a professional service. Here’s a typical flow:

1. You Provide the Design: This is usually a 3D CAD file (like STEP or IGES). No drawing? A good service might help you create one, but that's another conversation.

2. DFM Feedback (This is Gold!): A great shop won't just quote blindly. They'll give Design for Manufacturability feedback. Like, "This internal corner is too sharp for a tool to reach, can we adjust it to save cost and time?" This step alone proves they're thinking with you.

3. Quotation & Agreement: You get a price based on material, machine time, setup, and finishing. For small batches, clear communication on timelines is crucial.

4. Production & Updates: The parts are machined. Some shops provide photos of the finished parts before shipping—a nice touch that builds trust.

5. Delivery & Support: You receive the parts. Need a tweak for version 2? That's where the relationship begins.

What to Look For in a Reliable Provider? (Beyond the Price Tag)

Don't just chase the lowest quote. For small batches, these factors often matter more:

✅ Communication & Responsiveness: Do they answer emails quickly? Do they ask clarifying questions about your design intent?

✅ Willingness to Offer Advice: As mentioned, DFM suggestions are a huge green flag. It shows expertise and a partnership mindset.

✅ Transparency in Pricing Breakdown: Does the quote vaguely say "machining cost," or does it itemize material, programming, setup, and run time? Transparency suggests fairness.

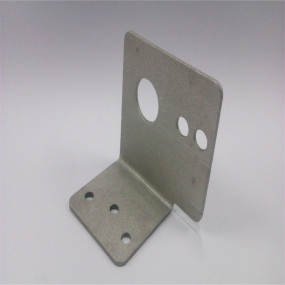

✅ Their Own "Small-Batch" Vibe: Look at their website and case studies. Do they showcase prototype parts or short runs? Or is it all pictures of massive production lines?

From my experience, a shop that's slightly more expensive but excels in these areas will save you more money (and headaches) in the long run by getting it right the first time. Perhaps this indicates that the true cost isn't just on the invoice, but includes the time you spend managing errors.

Common Materials and Finishes for Your Small Batch Project

These services typically work with a wide range of materials. Common choices include:

Metals: Aluminum (easy to machine, lightweight), Stainless Steel (strong, corrosion-resistant), Brass, and Mild Steel.

Plastics: Delrin (POM), Nylon, ABS, PTFE (Teflon).

After machining, parts often need finishing. Think anodizing for aluminum (adds color and hardness), bead blasting for a uniform matte texture, or simple deburring to remove sharp edges. A full-service shop will guide you here based on your part's function.

Ready to Get Your Precise Parts Made?

If you're tired of hitting dead ends with shops that don't get the small-batch struggle, it's time to talk to a team that does. We focus on turning your complex designs into reality, one small batch at a time, with the precision and care your project deserves. Have a CAD file ready? Let's discuss how we can help you move from concept to functional parts seamlessly.

👉 Click the chat widget now to connect directly with our engineering team for a free project review. No automated quotes—just a real conversation.

In this world of mass production, there's something deeply satisfying about crafting a few perfect pieces. It's where engineering feels most like art. 🛠️✨

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque