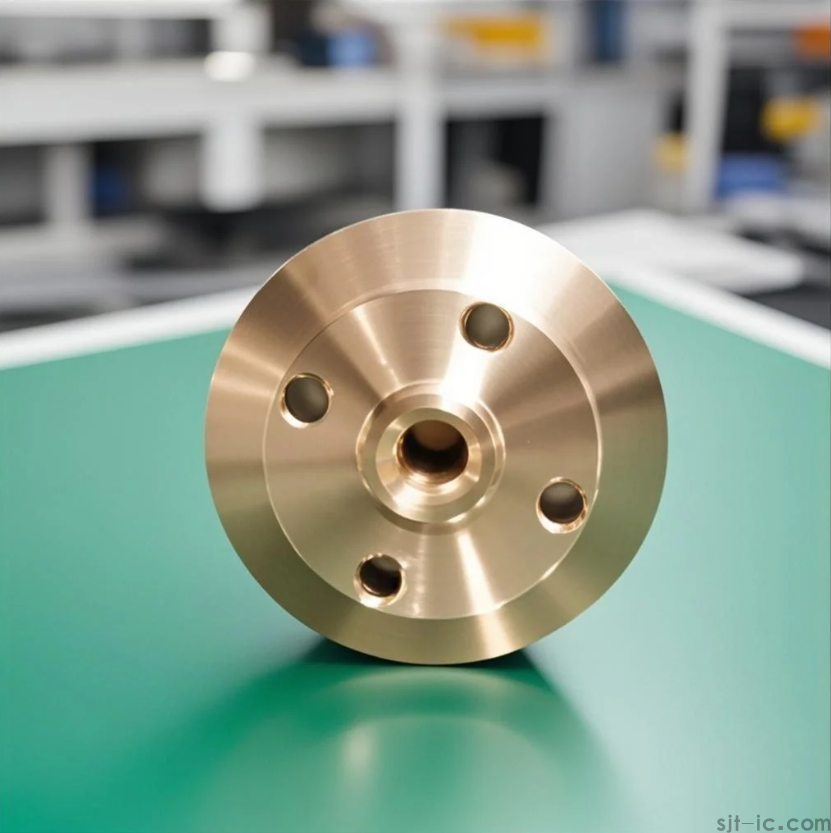

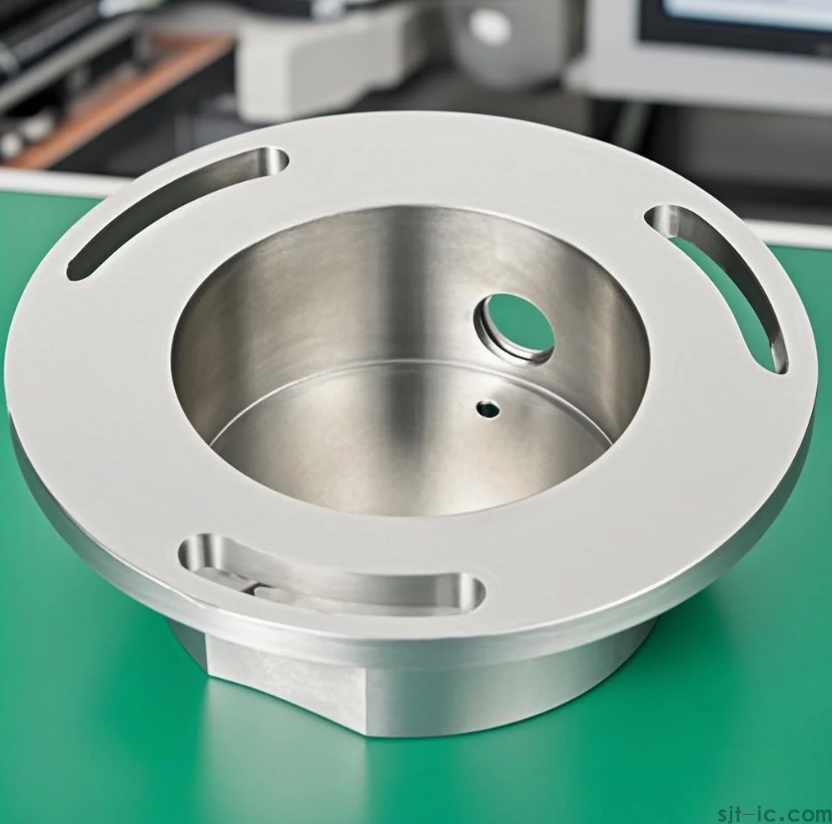

Hey there, fellow engineers and procurement specialists! 👋 Ever found yourself staring at a technical drawing for a stainless steel flange, wondering just how tight those tolerance callouts can realistically be held in real-world production? You're not alone. We all want the perfect part, but between the ideal design and the finished piece sitting on your inspection table, there's a whole world of machining reality. So, let's cut through the marketing fluff and talk brass tacks: What level of precision is actually achievable when CNC Machining a stainless steel flange?

The Short Answer (Because You're Busy)

For most common stainless steel grades like 304 or 316, a skilled CNC machining shop can consistently achieve dimensional tolerances of ±.01mm to ±.05mm (±.0004" to ±.002") on critical features like bore diameters, bolt hole circles (BHC), and face flatness. For surface finish, Ra .8μm to 3.2μm (32 to 125 μin) is readily attainable. Now, that's a solid benchmark, but—and here's the kicker—it's not a guarantee for every single feature on every single flange. It depends. Let's unpack that.

It's Not Just About the Machine (The "It Depends" Factors)

Okay, so you see a shop has fancy 5-axis CNC centers. Great! But the machine is just one piece of the puzzle. Think of it like a race car; the hardware is vital, but the driver, the pit crew, and the track conditions matter just as much.

Here’s what really drives the achievable precision:

- 🛠️ The Flange Design Itself: A compact, symmetrical flange is way easier to hold tight on than a massive, thin-walled, oddly-shaped one. Thin sections can warp from heat and cutting forces.

- 🧪 Stainless Steel Grade & Condition: 316 stainless might machine a bit differently than 304. And is it annealed? Work-hardened? Material consistency is key.

- 👨🔧 Tooling & Setup Wisdom: This is where the operator's experience shines. Using the right cutting tools, coolant strategy, and work-holding method (a beefy vise vs. a custom fixture) makes a world of difference. I've seen setups where 80% of the battle for precision was won before the first tool even touched the metal.

📏 Measurement & Calibration: Can the shop actually measure what they claim? Having a CMM (Coordinate Measuring Machine) on the floor is a good sign they're serious about verification.

Pushing the Limits: When You Need "Extreme" Precision

Sometimes, ±.05mm just won't cut it. You need that bore to be IT7 grade or the face runout to be under .005mm. Is it possible? Technically, yes. But be prepared for a different conversation.

This level often requires:

- Multiple finishing passes and dedicated "sizing" operations, which skyrockets machining time and cost.

- A strictly controlled environment (temperature swings are the enemy of ultra-precision).

- Post-machining processes like lapping or honing to hit that mirror finish or final micron-level dimension.

My personal take? Always ask if you *truly* need that last micron. Over-specifying tolerances can inflate your part cost by 300% or more for no functional benefit. It's a classic engineering trade-off.

The Proof is in the Process (Not Just the Brochure)

So how do you know a shop can deliver what they promise? Don't just look at their best-case-scenario spec sheet. Ask for evidence that matters in *your* context.

Ask them these questions:

- "Can you show me a First Article Inspection (FAI) report for a similar stainless steel part you've made?" This shows real data.

- "What is your typical process capability index (Cpk) for holding a ±.02mm tolerance on stainless?" This separates consistent performers from one-hit wonders.

- "Walk me through your quality control workflow for a precision flange job." Their answer will tell you if precision is built into their process or just an afterthought.

This approach might hint at a more reliable partnership than just going with the shop that quotes the tightest number upfront.

Okay, But What Should I Do Now?

Feeling clearer but maybe a bit overwhelmed? That's normal. Precision isn't a single number you order off a menu; it's the outcome of a capable process applied to your specific design.

Here's my advice: Start a conversation with your potential supplier early. Share your drawings, highlight the *truly* critical features, and discuss the application. A good machining partner will tell you straight up what's easy, what's challenging, and what's going to cost a fortune. They might even suggest a design tweak that saves you money with zero performance loss.

👉 Ready to see what's achievable for your specific stainless steel flange design? The best next step is to get a professional opinion based on your actual prints. Reach out to our technical team with your drawings – let's turn those precision questions into a solid, manufacturable plan.

Hope this deep dive helps you navigate your next project! 🤝

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque