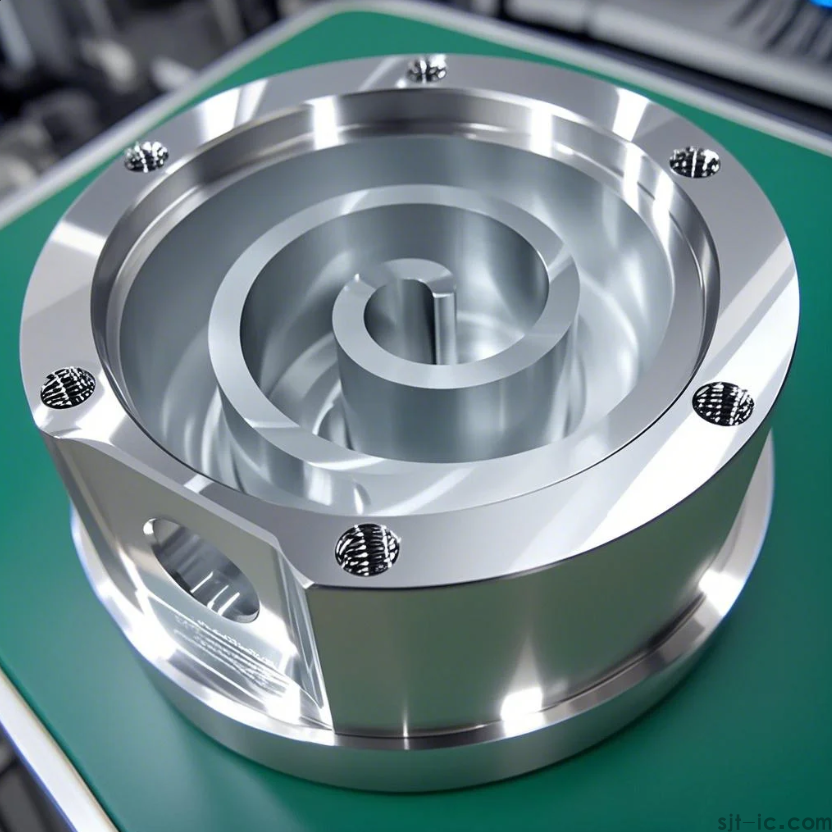

As a leading CNC Machining service provider, EMAR specializes in delivering precision aluminum product custom machining solutions for industrial applications. Our advanced manufacturing capabilities ensure exceptional quality and dimensional accuracy for your custom aluminum components.

Why Choose CNC Machining for Aluminum Products?

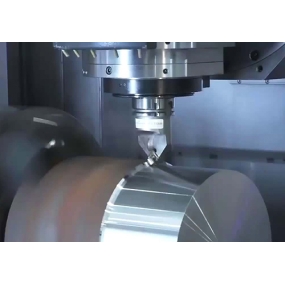

Aluminum's excellent machinability makes it ideal for CNC aluminum product custom machining. Our 5-axis CNC machines achieve tight tolerances (±.01mm) while maintaining high production efficiency. The process offers superior surface finishes and complex geometries unattainable through conventional methods.

Our Custom Machining Process

1. Material Selection: We work with 6061, 7075, and other aerospace-grade aluminum alloys

2. CAD/CAM Programming: Our engineers optimize tool paths for efficiency and precision

3. Precision Machining: State-of-the-art CNC mills and lathes perform the operations

4. Quality Inspection: CMM and surface roughness testers verify all specifications

Applications of CNC Machined Aluminum Parts

Our custom aluminum components serve critical functions in:

- Aerospace structural parts

- Automotive prototypes

- Electronics enclosures

- Medical device components

- Robotics systems

EMAR's Competitive Advantages

• 15+ years of CNC machining expertise

• ISO 9001:2015 certified quality system

• Fast turnaround (as quick as 72 hours)

• Competitive pricing for bulk orders

• Comprehensive post-processing options

Contact EMAR today at www.sjt-ic.com for your custom aluminum machining projects. Our engineering team provides DFM analysis and technical support throughout your product development cycle.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque