Ever found yourself staring at a complex part design wondering: "Do I really need 4-axis machining for this?" 🤔 You're not alone. Many purchasing managers and engineers struggle with this exact question when sourcing precision parts. Let's break it down in plain English.

So What Exactly Are We Talking About Here?

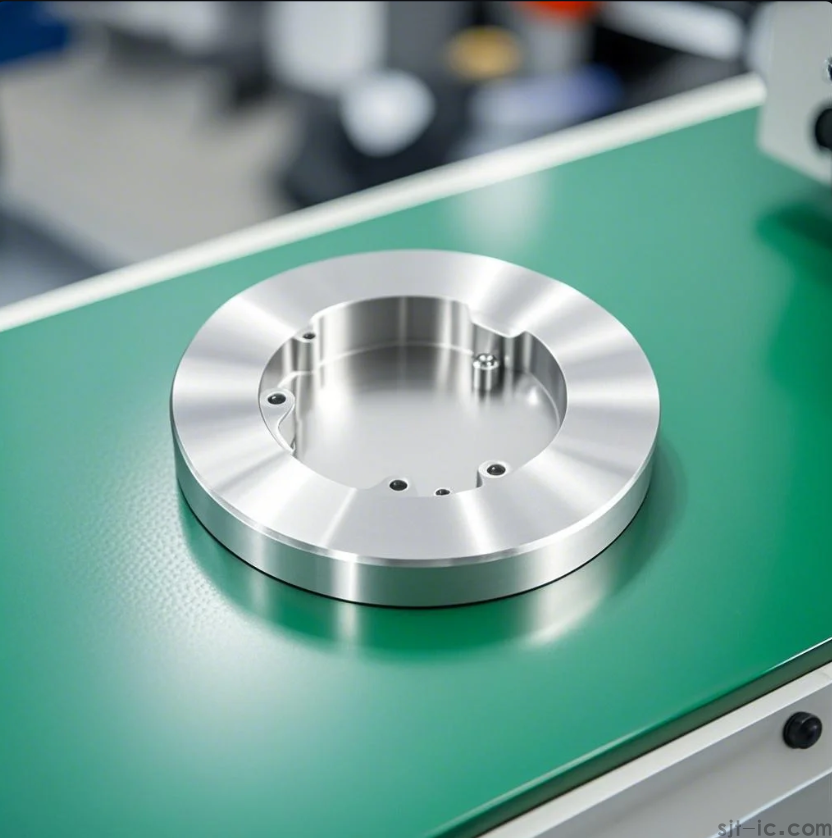

3-axis CNC Machining moves cutting tools along three directions: up-down, left-right, and forward-backward. It's like a very precise robot hand that can reach anywhere in a box-shaped space. 4-axis adds rotation around one horizontal line, giving that "twisting" motion that opens up new possibilities.

When Should You Choose 3-Axis Machining?

• Flat parts and simple geometries - If your part looks basically "flat" or has features mostly on one side

• Tighter budgets - 3-axis machines cost less to operate hourly

• Faster turnaround for simple jobs - No need for complex setup rotations

I've seen companies waste thousands specifying 4-axis for parts that could be made perfectly well on 3-axis equipment. Sometimes simpler really is better.

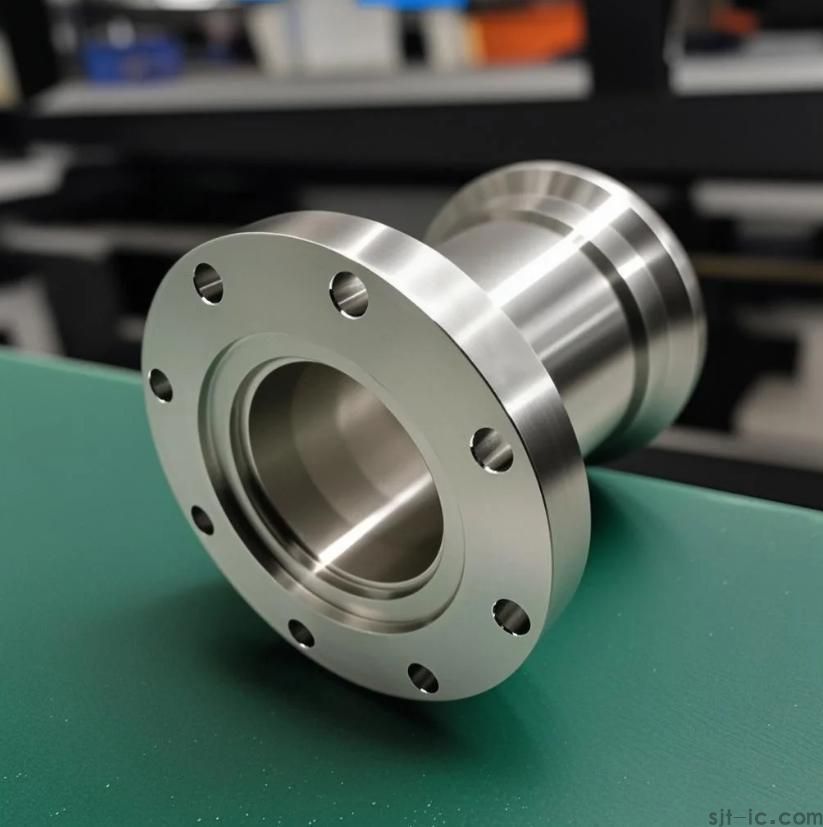

That Fourth Axis - When Does It Actually Matter?

Here's where things get interesting. The rotation capability isn't just a "nice to have" - it becomes essential for:

• Parts needing machining on multiple sides - Like those with holes or features wrapped around

• Complex contours - Think curved surfaces that aren't just simple arcs

• Reducing setup time - One 4-axis setup vs. multiple 3-axis setups

Though honestly, I've noticed some shops push 4-axis for jobs that could be done in two 3-axis operations. You need to ask: "Will the reduced handling time actually save money?"

The Cost Question Everyone's Thinking About

4-axis machining typically runs 20-40% higher per hour than 3-axis. But here's the twist (pun intended) - sometimes using 4-axis actually saves money overall.

Let me explain: If a part requires machining on three sides, with 3-axis you'd need:

1. First setup - machine top features

2. Second setup - flip part, machine bottom

3. Third setup - reposition, machine sides

Each setup takes time and introduces potential alignment errors. With 4-axis, you might do it in one setup.

This perhaps suggests that focusing solely on hourly rates can be misleading. The total job cost matters more.

Making The Right Choice For Your Project

Ask yourself these questions:

• How many sides need machining?

• Are there features that wrap around the part?

• What's your tolerance requirement?

• What's the production quantity?

For one-off prototypes, multiple 3-axis setups might be cheaper. For production runs, 4-axis often wins on consistency and speed.

That being said, I've found that many parts fall into a gray area where either method could work. In these cases, getting quotes for both approaches makes sense.

The Quality Consideration Many Overlook

Here's something I wish more buyers knew: 4-axis machining can sometimes deliver better accuracy on complex parts. Why? Because reducing the number of times you re-clamp the workpiece minimizes cumulative positioning errors.

I recall a client who kept getting slightly out-of-spec parts with 3-axis machining. The issue wasn't the machine's precision - it was the tiny variations introduced each time they repositioned the part. Switching to 4-axis solved their tolerance problem.

Still, it's worth mentioning that a skilled 3-axis operator with good fixtures can achieve remarkable accuracy too. The machine is only part of the equation.

Looking for personalized advice on your specific machining project? Our technical team can help you choose the most cost-effective approach - just reach out through our contact form and we'll analyze your drawings within 24 hours. 📄→📞

Industry data shows that approximately 60% of parts currently made on 4-axis machines could be produced on 3-axis equipment with careful process planning. The reverse isn't true - some geometries simply require that additional rotational freedom.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque