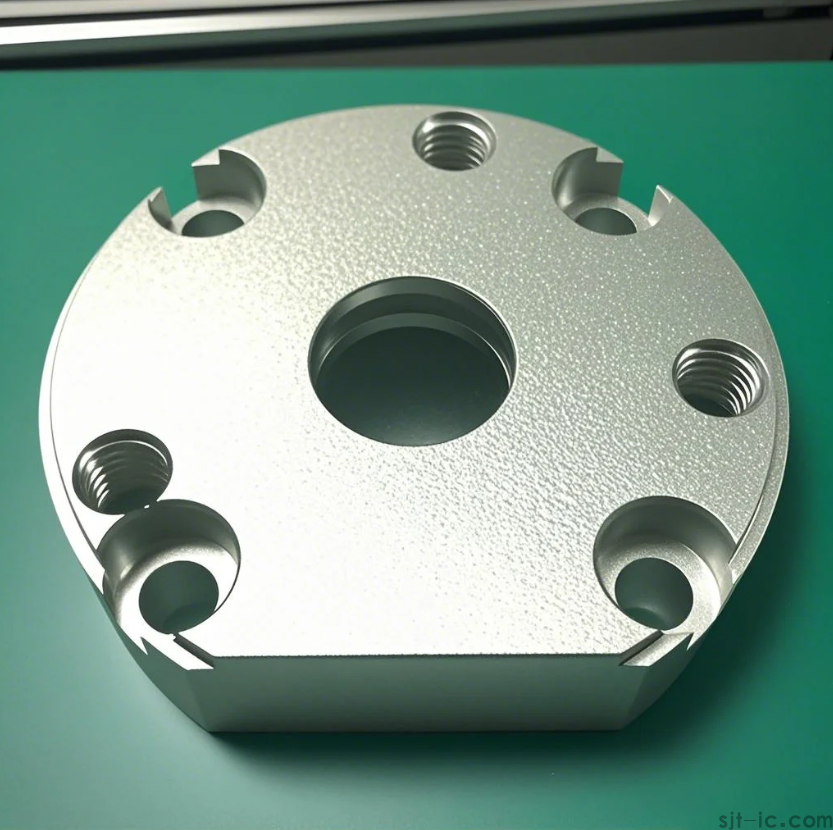

What is CNC Parts Machining?

CNC (Computer Numerical Control) parts machining is a high-precision manufacturing process that uses computerized controls to operate machine tools such as lathes, mills, and grinders. This technology enables the production of complex and customized components with tight tolerances, making it ideal for industries like aerospace, automotive, medical, and electronics.

At EMAR, we specialize in delivering top-quality CNC machined parts that meet the most demanding specifications. Our advanced equipment and skilled technicians ensure every component is crafted with accuracy and efficiency.

Advantages of CNC Parts Machining

1. Unmatched Precision and Consistency

CNC Machining eliminates human error, ensuring each part is produced with exact dimensions and repeatability. This is crucial for industries requiring tight tolerances.

2. Wide Material Compatibility

From aluminum and stainless steel to plastics and exotic alloys, CNC machining supports a broad range of materials to suit different applications.

3. Fast Turnaround & Cost Efficiency

Automated processes reduce production time while maintaining high quality, making CNC machining a cost-effective solution for both prototypes and large-scale production.

EMAR’s CNC Machining Capabilities

5-Axis CNC Milling – Complex geometries with superior surface finishes.

CNC Turning – High-precision cylindrical parts.

Prototyping & Mass Production – From concept to final product.

Strict Quality Control – ISO-certified inspections for flawless results.

Why Choose EMAR for CNC Parts Machining?

As a trusted CNC machining service provider, we combine cutting-edge technology with decades of expertise to deliver durable, high-performance components. Our commitment to customer satisfaction and on-time delivery makes us a preferred partner for global manufacturers.

Visit EMAR’s official website to explore our full CNC machining solutions!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque