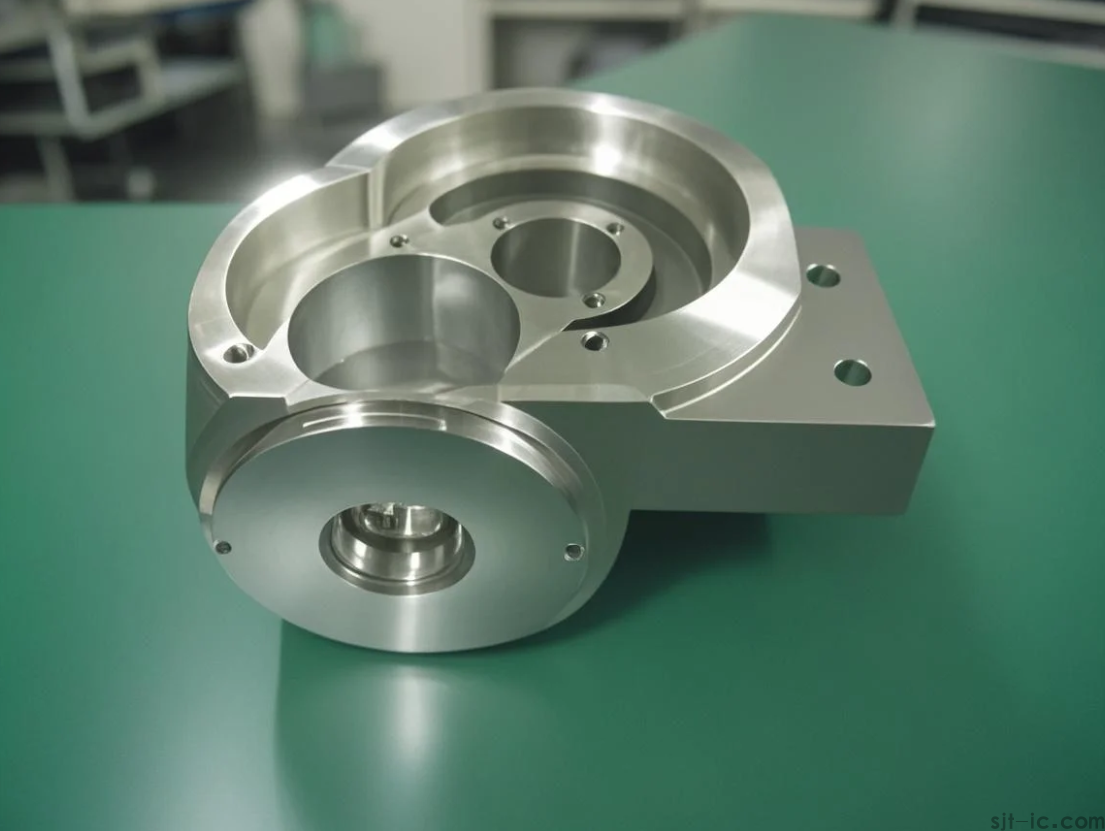

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision brake system parts for automotive, aerospace, and industrial applications. Our CNC machining capabilities ensure exceptional dimensional accuracy and surface finish for critical braking components.

Why Choose CNC Machining for Brake Components?

Brake systems demand components with tight tolerances (typically ±.01mm), excellent heat resistance, and structural integrity. Our 5-axis CNC machines produce:

Brake calipers with complex internal channels

Precision brake pistons with mirror finishes

Mounting brackets with perfect flatness

Rotor hubs with balanced weight distribution

Material Selection for Brake Parts

We machine various materials for brake applications:

Aluminum alloys (6061-T6, 7075) for lightweight calipers

Stainless steel (304, 17-4PH) for corrosion resistance

Titanium for high-performance racing systems

Carbon composites for advanced aerospace brakes

EMAR's Quality Assurance Process

Every brake component undergoes rigorous testing:

3D coordinate measurement (CMM) verification

Surface roughness analysis (Ra ≤ .8μm)

Pressure testing up to 300psi

Material composition certification

With ISO 9001-certified production and 15+ years of experience in CNC machining, EMAR delivers brake components that meet SAE, DIN, and ISO automotive standards. Contact our engineering team at www.sjt-ic.com for customized solutions.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque