As a leading CNC Machining service provider, EMAR Company understands that CNC aluminum parts machining price is a critical factor for procurement managers and engineers when selecting manufacturing partners. This article will break down the pricing structure and showcase how we deliver optimal cost-performance ratios.

Factors Affecting CNC Aluminum Machining Costs

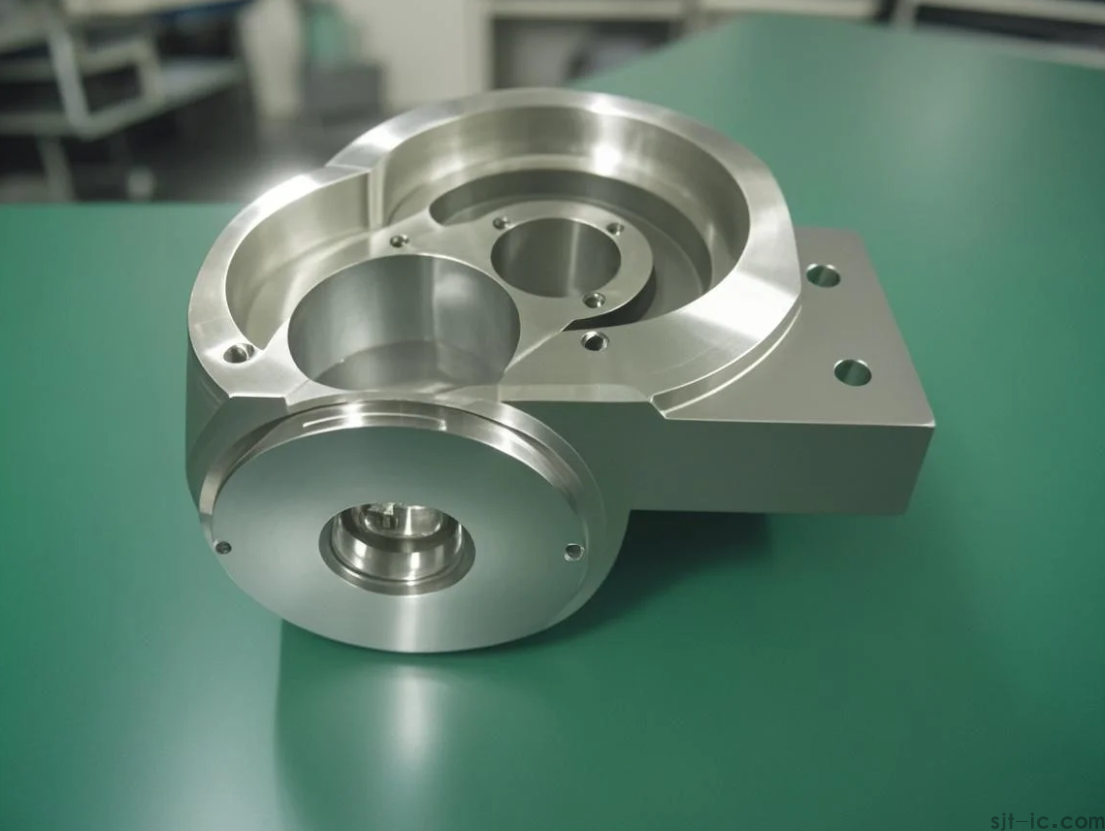

The pricing of CNC aluminum products depends on multiple variables: material grade (6061, 7075, etc.), part complexity, tolerance requirements, surface treatment needs, and order quantity. Our ISO-certified facility utilizes advanced 5-axis CNC machines to optimize material usage and reduce waste, directly lowering your per-unit costs.

EMAR's Transparent Pricing Model

Unlike competitors with hidden fees, we provide detailed quotations including: raw material costs, machine time (based on CAD analysis), finishing processes, and quality control expenses. For bulk orders (500+ pieces), we offer tiered discounts while maintaining aerospace-grade precision.

Cost-Saving Strategies We Implement

1. Design for Manufacturability (DFM) analysis - Our engineers suggest modifications to reduce machining hours without compromising function

2. Nesting optimization - Maximizing material utilization from each aluminum billet

3. Secondary process integration - Combining anodizing/powder coating in-house to eliminate third-party markups

Why EMAR Delivers Better Value

With 15+ years specializing in precision aluminum components, we've refined processes to achieve 30% faster turnaround than industry averages. Our vertically integrated facility (from CNC milling to final inspection) ensures consistent quality while controlling costs. Request a free project evaluation at www.sjt-ic.com to receive your competitive quote within 24 hours.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque