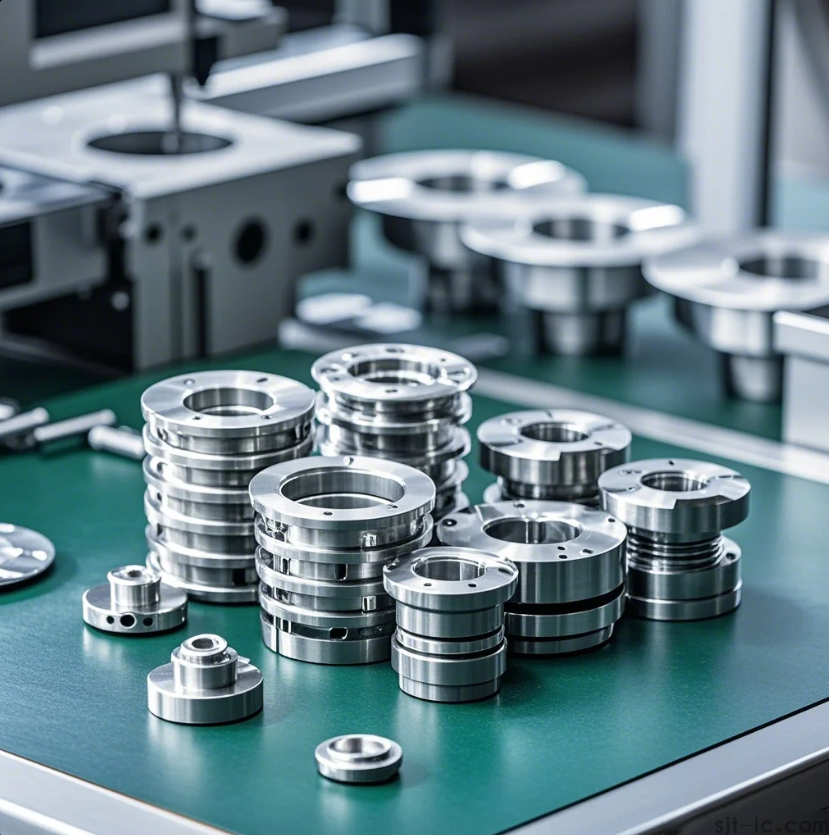

In modern manufacturing, CNC mass small parts machining plays a pivotal role in industries ranging from electronics to automotive. As a leading CNC Machining service provider, EMAR specializes in delivering high-precision, cost-effective solutions for bulk production of miniature components. This article explores the technical advantages, process optimization, and how our expertise ensures your project's success.

Why Choose CNC Machining for High-Volume Small Parts?

CNC technology excels in producing identical small components with micron-level accuracy across thousands of units. Our 5-axis machines and Swiss-type lathes handle complex geometries in materials like aluminum, brass, and engineering plastics. The automated nature of CNC mass production eliminates human error while maintaining ±.005mm tolerances consistently.

EMAR's Advanced Capabilities

At EMAR, we've optimized our workflow specifically for small-part batches:

Dedicated high-speed machining centers (40,000 RPM spindles)

Automated part handling systems for continuous operation

In-line quality inspection with laser measurement

Material-saving nesting software to reduce waste

Industry Applications

Our solutions serve critical needs in:

Electronics: Connector pins, shielding components

Medical: Surgical instrument parts, implant fixtures

Automotive: Fuel injection components, sensor housings

Cost-Effective Production Strategies

We implement design-for-manufacturing (DFM) analysis to recommend material alternatives and tolerance adjustments that can reduce your per-unit cost by 15-30% without compromising functionality.

Ready to optimize your small parts production? Contact EMAR's engineering team for a free project evaluation and sample quote.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque