Understanding CNC Plastic Steel Machining

CNC plastic steel machining process refers to the precision manufacturing technique used to shape and fabricate plastic steel materials through computer numerical control systems. This advanced process combines the durability of steel with the versatility of plastic, creating components with exceptional strength-to-weight ratios and corrosion resistance.

Key Advantages of Our CNC Plastic Steel Machining

EMAR Company specializes in delivering high-quality CNC plastic steel machining services with several distinct advantages:

±.005mm precision tolerance for critical dimensions

Advanced tooling solutions for reduced material waste

Multi-axis machining capabilities for complex geometries

Strict quality control measures at every production stage

The EMAR Manufacturing Process

Our comprehensive CNC Machining process for plastic steel involves:

Material selection and verification

Precision CAD/CAM programming

Multi-stage machining operations

Surface finishing and treatment

Final inspection and quality assurance

Applications Across Industries

CNC machined plastic steel components serve critical functions in:

Automotive lightweight structural parts

Medical device housings and components

Aerospace interior fittings

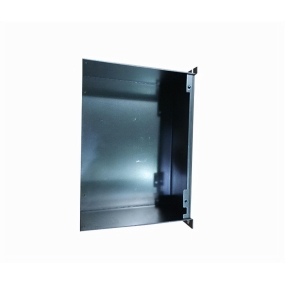

Industrial equipment protective casings

Consumer electronics durable frames

Why Choose EMAR for Your CNC Plastic Steel Needs

With our state-of-the-art facility at www.sjt-ic.com, EMAR delivers unmatched expertise in CNC plastic steel machining. Our team of skilled technicians, combined with advanced machinery and rigorous quality standards, ensures components that meet the most demanding specifications. We offer competitive pricing, fast turnaround times, and customized solutions tailored to your specific requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque